Tabletop CNC Lathe

Tabletop CNC Lathe Specification

- Product Type

- Tabletop CNC Lathe

- General Use

- Education, Small component manufacturing, Prototyping

- Material

- Body: Cast Iron, Working Parts: Steel

- Type

- CNC Lathe

- Capacity

- Turning Diameter up to 85 mm; Turning Length up to 180 mm

- Weight (kg)

- Approx. 110 kg

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Integrated PLC Control

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 750 W

- Rigidity

- High rigidity cast iron bed

- Voltage

- 220 V

- Motor

- 0.75 kW AC Motor

- Spindle Speed

- 100 - 2500 RPM

- Axial Choice

- 2 Axis (X/Z)

- Dimension (L*W*H)

- Approximately 800 x 500 x 600 mm

- Feature

- Compact size, Precision machining, Easy operation, Safety guards

- Color

- Blue & White

- Min Input Unit

- 0.001 mm

- Chuck Type

- 3-Jaw Self-centering Chuck

- Tool Post

- 4-way tool post

- Tailstock

- Manual, Adjustable

- Repeatability

- ±0.01 mm

- Coolant System

- Optional

- Application

- Training institutes, Hobby workshops, Light manufacturing

- Noise Level

- Less than 70 dB

- Control System

- Microcontroller based CNC system

- Display

- LCD Touch Screen

- Ball Screw

- Preloaded ball screws for X/Z axes

- Spindle Bore

- 20 mm

- Working Environment

- 0°C to 45°C, Less than 80% RH (non-condensing)

Tabletop CNC Lathe Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- Set

- Delivery Time

- 15 Days

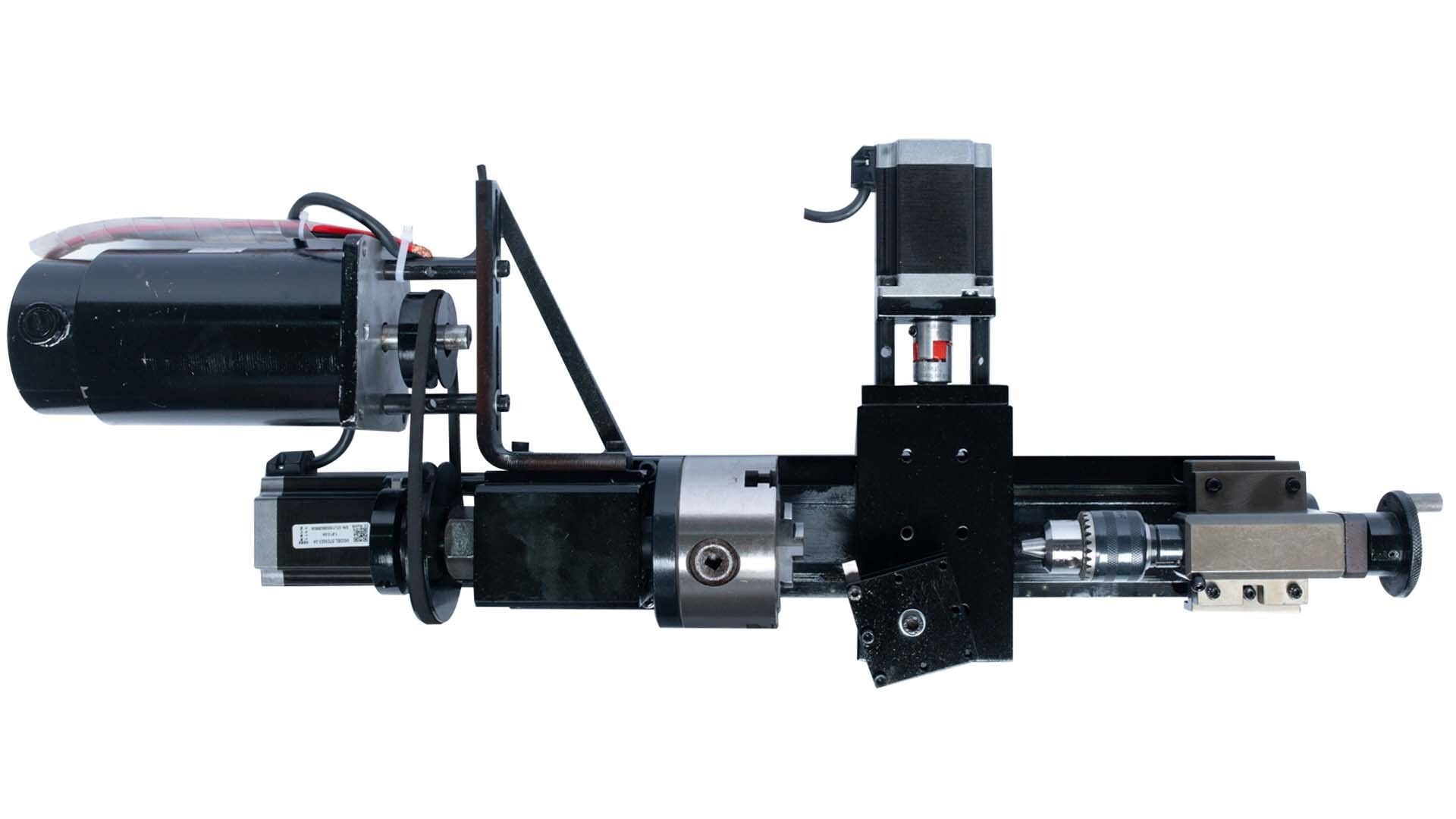

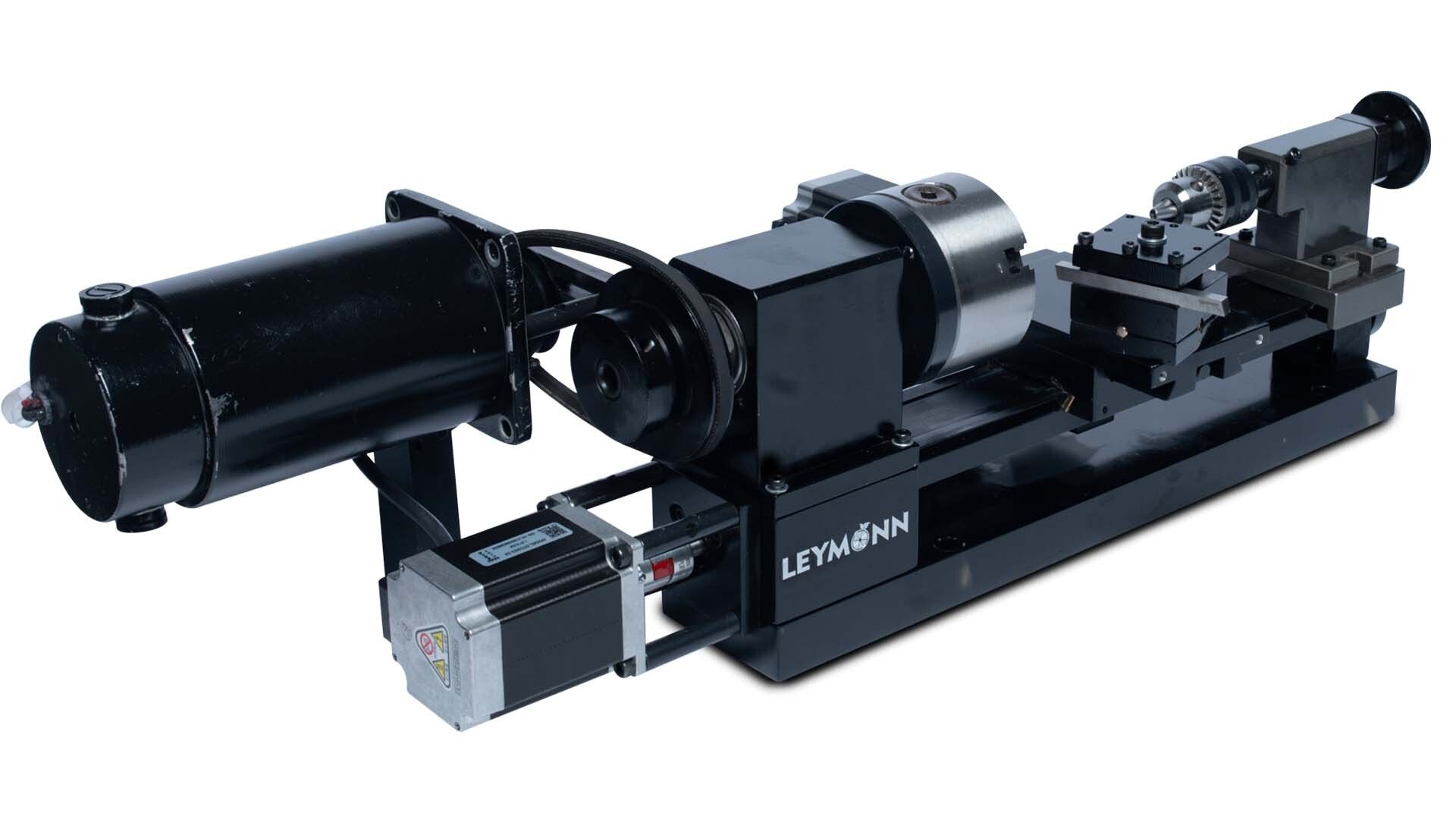

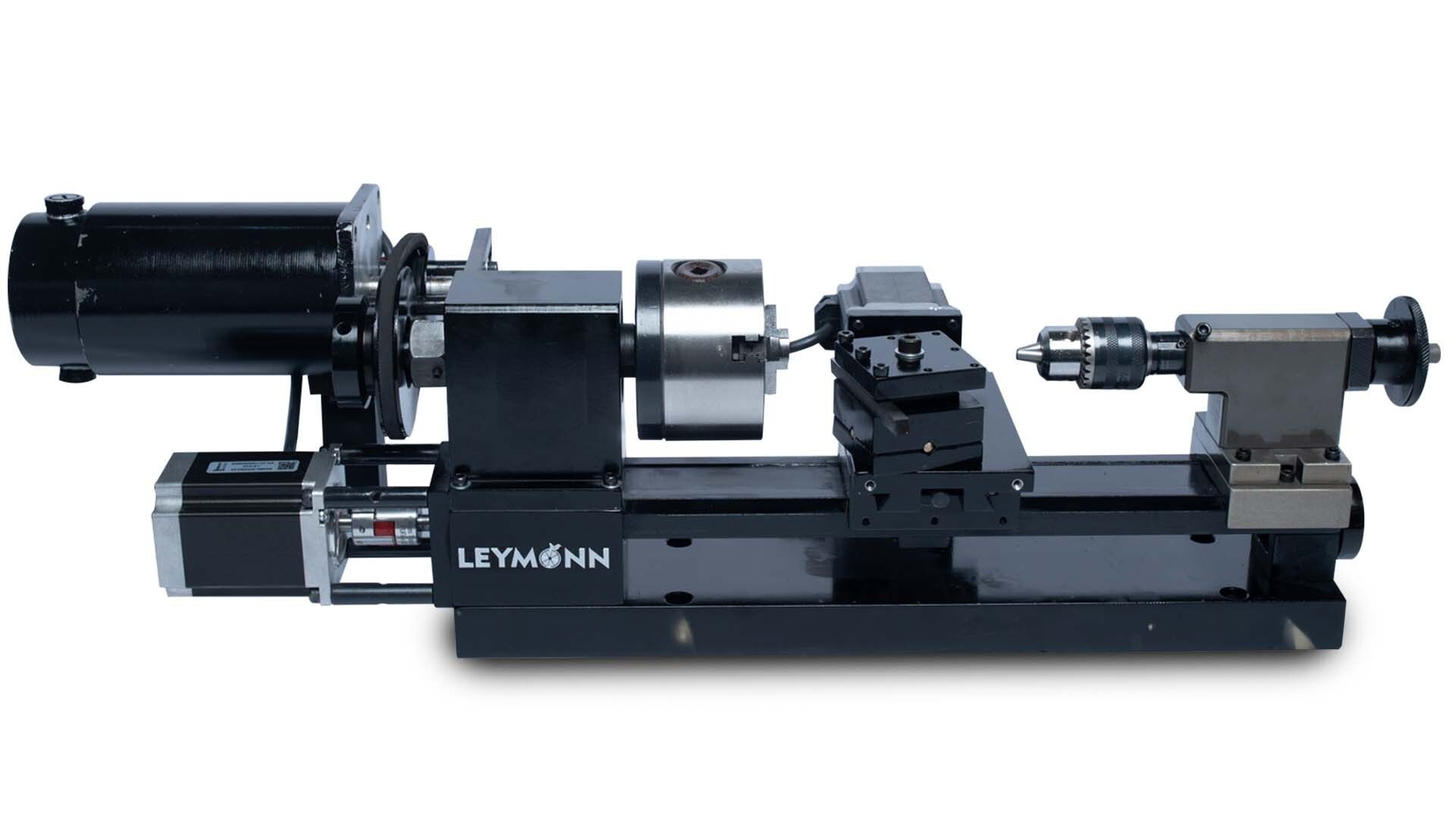

About Tabletop CNC Lathe

Tabletop CNC Lathe

Technical Specifications:

- X-Trevel : 60 MM

- Z-Travel 240MM

- Hole through spindle: 10MM

- Table L X W: 150x70MM

- Overall dimensions L x W x H: 700X190X190

- Approx wt: 20Kg

- Software: MACH3

Features:

- Suitable for ITIs, Engineering Colleges and all types of medium and small Engineering and Hobby Shops

- Compact and Light weight only 25 Kgs!

- Perfect for small jobs machining.

- PC based system

- Easy to operate. Even a school student can learn to operate the machine within an hour.

- Spindle speeds infinitely variable from 100-3000 RPM.

- Very easy Electronic spindle speed adjustment.

- Proven and user friendly Mach3 interface.

Standards:

- Machine tool with two stepper motors on X and Z axes

- Precision Three jaw scroll chuck mounted on spindle.

- DC motor with speed control unit for spindle

- Four position manual tool turret.

- Tail-stock with 6 mm drill chuck.

Options

- AC motor with VFD

- Servo motors for all three axes and

- Tail-stock with 10 mm drill chuck.

- Four position automatic tool turret

- Four jaw dog chuck

Machine Specification

|

Centre Height |

120 MM |

|

Swing Over Carriage |

60 mm / 110mm |

|

Distance Between Centers |

200mm |

|

Max. Machining Diameter |

110mm |

|

Max. longitudinal Travel |

240 mm |

|

Table Length with T Slot |

150mm X 75mm |

|

Z Axis traverse |

240 mm |

|

X Axis traverse |

60 mm |

|

Spindle Inside Taper |

MT1 |

|

Spindle Speed |

100-3000RPM Infinitely variable |

|

Cross Slide Inclination |

0 Degrees |

|

Cutting Tool Size |

6x6 mm |

|

Spindle motor DC Motor |

160W DC Motor |

|

Threading |

Straight/Taper |

|

Automatic Lubrication |

Optional |

|

Input System |

Metric/ Inch |

|

Control Axes |

Simultaneous axes |

|

Interpolation |

Linear, Circular, elliptical and Parabolic |

|

Minimum increment |

0.005 mm |

|

Minimum Movement command-X |

0.005 mm |

|

Minimum movement command -Z |

0.005 mm |

|

Repeatability |

0.02 mm |

|

Rapid Feed Rate X |

400 mm / min |

|

Rapid Feed Rate-Z |

800 mm / min |

|

Dwell (Seconds) |

Programmable |

|

Tool Offset with Turret / ATC |

|

|

Backlash compensation |

Provided |

|

Speed override |

40%-160% |

|

Feed override |

20%-120% |

|

Type of Control system |

PC based system |

|

Real Time Tool Path Simulation |

Provided |

|

General Parameters |

|

|

Floor Area |

700 mm x 500 mm |

Precision and Compactness

Engineered for consistent accuracy, the CNC lathe delivers repeatability of 0.01 mm and features a compact footprint (800 x 500 x 600 mm), ideal for confined spaces. The machine is crafted from cast iron for high rigidity, minimizing vibration and enhancing machining results, particularly for small components and prototypes.

Easy-to-Use CNC Control

The integrated microcontroller-based CNC system and touch screen LCD interface simplify operation, making the lathe suitable for both beginners and experienced users. Automated 2-axis control with PLC integration allows efficient programming and repeatable results, enhancing productivity in educational environments or light manufacturing.

Versatile Application

Designed for training institutes, hobby workshops, and small-scale manufacturing, this tabletop CNC lathe accommodates a range of tasks, from skill development to spare part fabrication. With manual, adjustable tailstock and optional coolant system, operators can tailor the machine setup to diverse projects and materials.

FAQs of Tabletop CNC Lathe:

Q: How does the Tabletop CNC Lathe ensure precise machining?

A: The lathe uses preloaded ball screws for both X and Z axes, providing minimal backlash and high repeatability of 0.01 mm. Combined with the rigid cast iron bed and microcontroller-based CNC system, it ensures accurate and consistent results during precision tasks.Q: What are the main benefits of using this CNC lathe in training institutes?

A: Its compact size, intuitive LCD touch screen interface, and safety guards make it safe and easy for students to operate. The precise controls and repeatability foster hands-on learning in CNC programming and machining, helping users gain real-world skills.Q: Where can the lathe be installed and used effectively?

A: This tabletop CNC lathe is suitable for educational classrooms, hobby workshops, and small-scale manufacturing setups. Its dimensions and noise level below 70 dB support use in confined, indoor environments with ambient temperatures between 0C to 45C and humidity up to 80% RH (non-condensing).Q: What processes or materials can be handled with this CNC lathe?

A: The lathe is optimized for turning operations on steel and other machinable materials, handling turning diameters up to 85 mm and lengths up to 180 mm. It suits tasks such as prototyping, precision component manufacturing, and educational projects.Q: How is safety addressed during operation of the machine?

A: Safety features include robust safety guards around moving parts and a highly rigid cast iron bed to maintain stability. Operators use an LCD touch screen interface for safe and controlled programming, and the machine runs at a noise level under 70 dB for a comfortable work environment.Q: What options are available for coolant and bar feeding?

A: An optional coolant system is available for enhanced machining and tool longevity. The lathe does not include a bar feeder, making it most suitable for discrete component or batch production rather than continuous automated feeding.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Machines Category

Tabletop CNC Mill

Price 1.20000 INR

Minimum Order Quantity : 1 Set

General Use : Metal Cutting, Prototyping, Education

Product Type : Tabletop CNC Mill

PLC Control : Other, Integrated

Rigidity : High

Desktop CNC Lathe

Price 1.20000 INR

Minimum Order Quantity : 1 Set

General Use : Precision Metal Turning, Prototyping, Educational Purposes

Product Type : Desktop CNC Lathe

PLC Control : Other, Available

Rigidity : Other, High Structural Rigidity

Cnc Twin spindle Gearteeth chamfering machine

Price 1600000.0 INR / Set

Minimum Order Quantity : 1 Set

General Use : CNC Machine

Product Type : Twin spindle Gearteeth chamfering machine

PLC Control : Yes

Rigidity : High

Cnc Sliding Head Automatic Machine

Price 980000.0 INR / Set

Minimum Order Quantity : 1 Set

General Use : CNC Machine

Product Type : Sliding Head Automatic Machine

PLC Control : Yes

Rigidity : High

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS