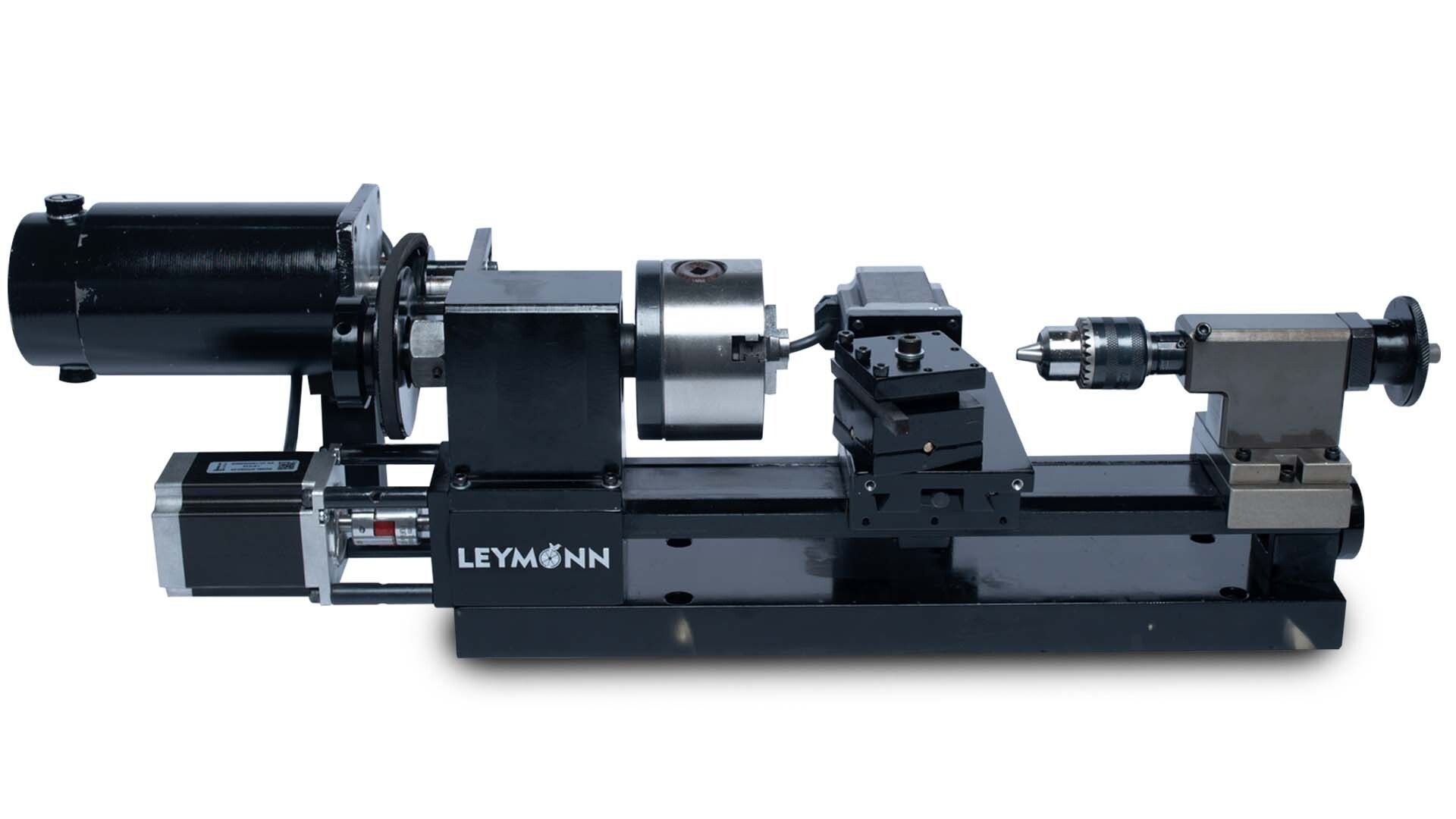

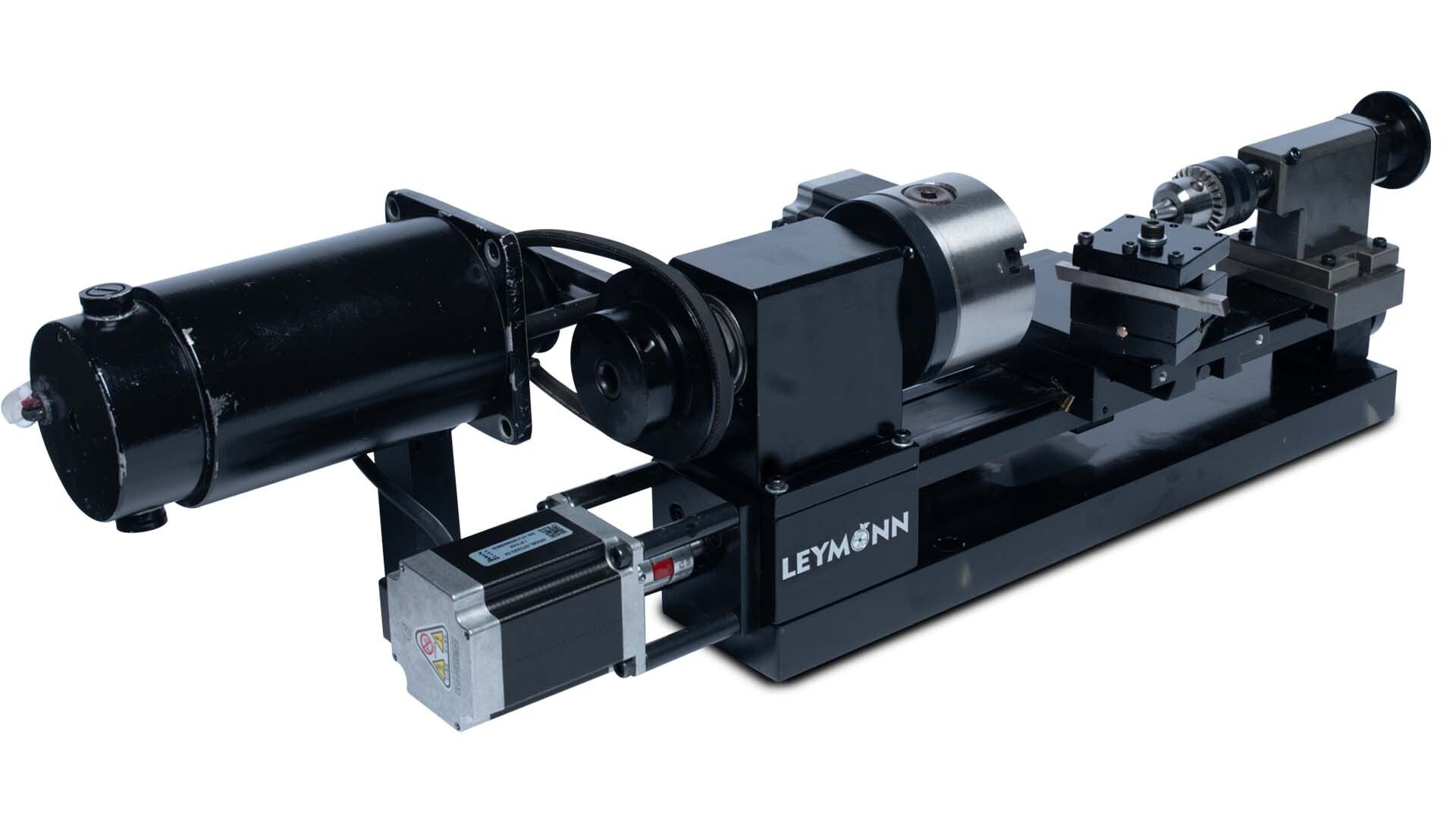

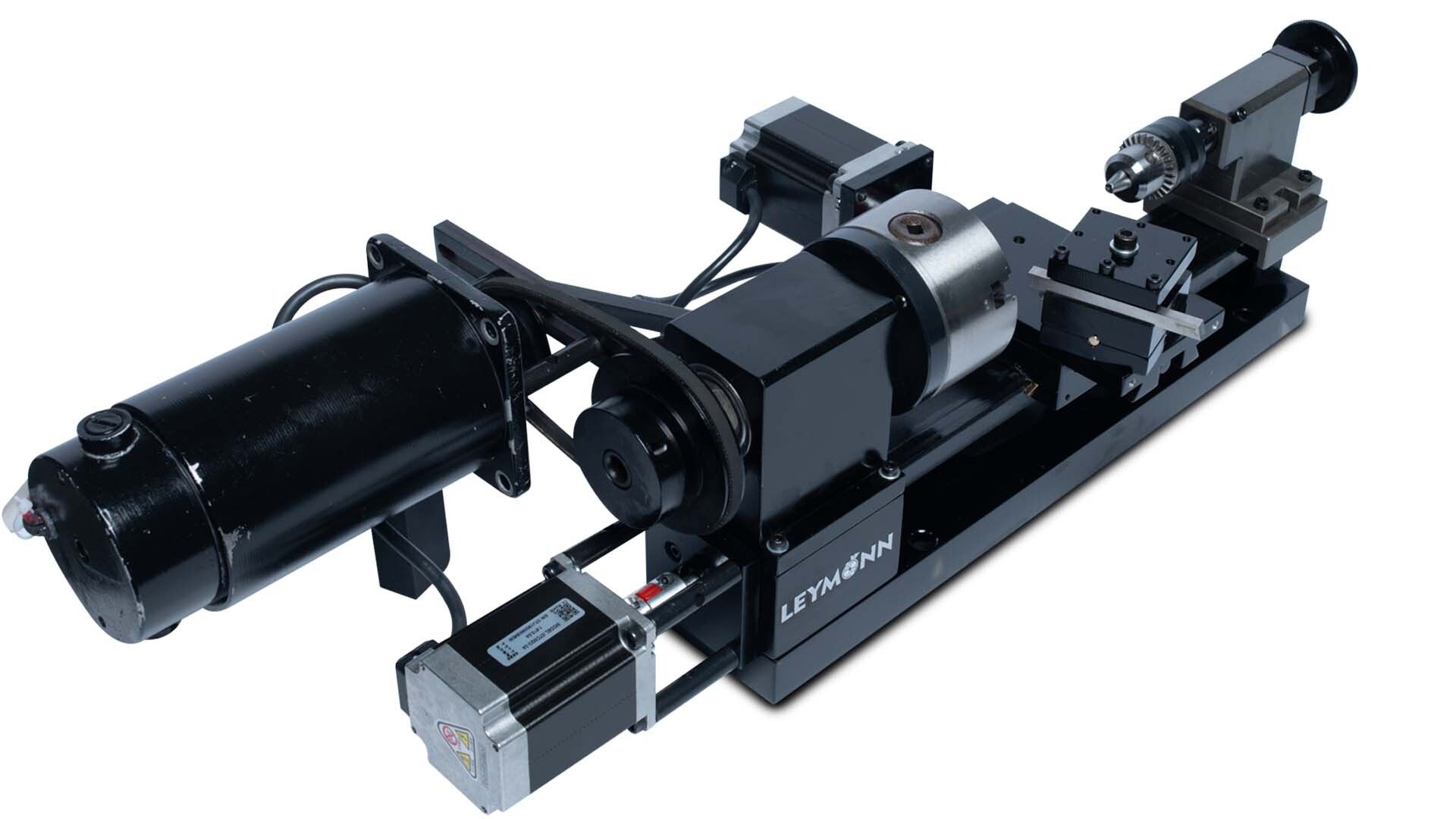

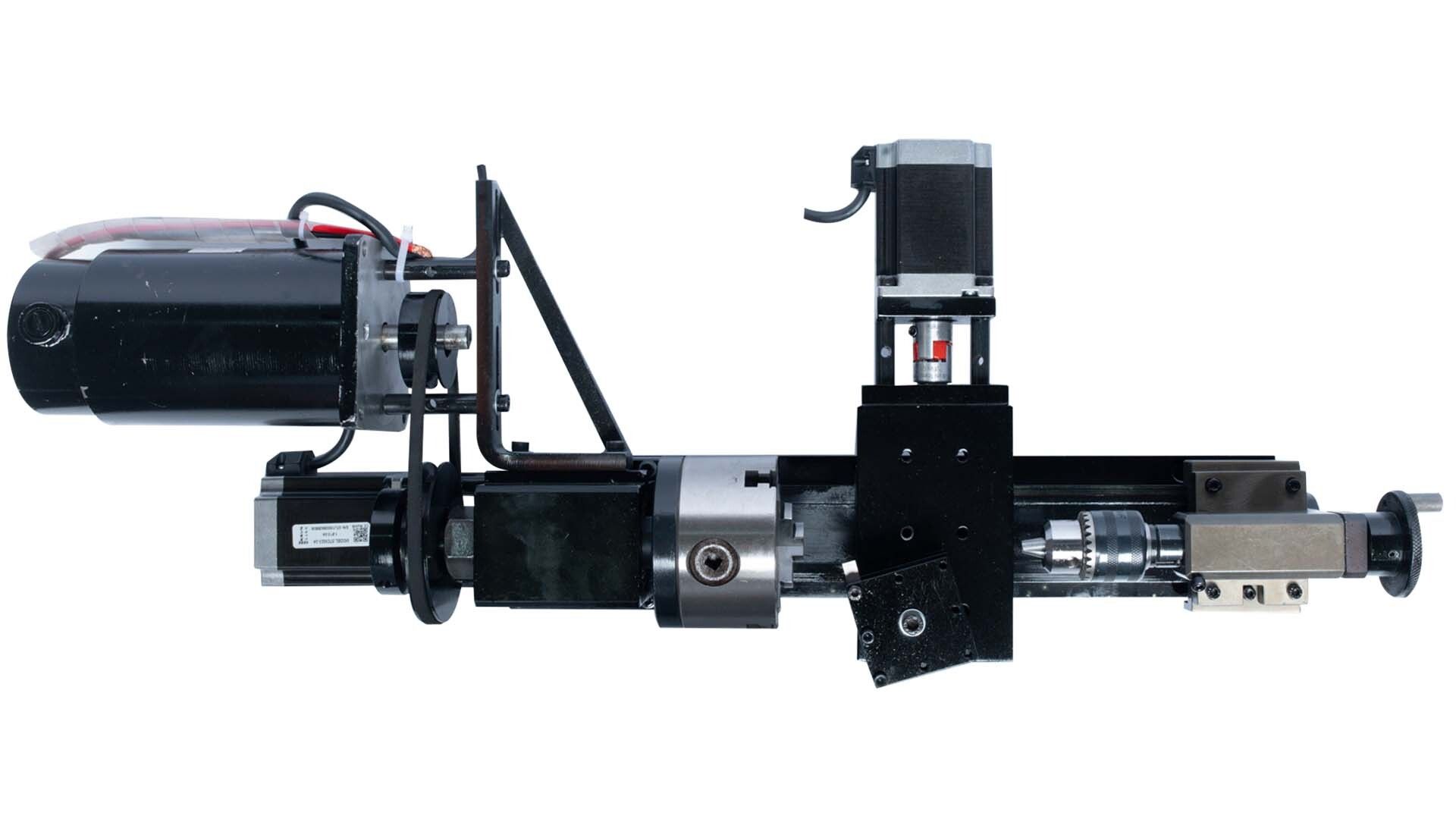

Desktop CNC Lathe

Desktop CNC Lathe Specification

- Product Type

- Desktop CNC Lathe

- General Use

- Precision Metal Turning, Prototyping, Educational Purposes

- Material

- Cast Iron Bed, Alloy Steel Components

- Type

- CNC Lathe

- Capacity

- Max Turning Diameter: 120 mm

- Weight (kg)

- 110 kg

- Computerized

- Yes

- Automatic

- Semi-Automatic

- PLC Control

- Available

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 1.5 kW

- Rigidity

- High Structural Rigidity

- Voltage

- 220V / 50Hz

- Motor

- Servo Motor

- Table Size

- 400 mm x 170 mm

- Spindle Speed

- 100-2500 RPM

- Axial Choice

- X, Z Axes

- Dimension (L*W*H)

- 760 mm x 600 mm x 580 mm

- Feature

- Compact Size, Precision Machining, Low Noise, User-Friendly Interface

- Color

- White & Blue

- Controller

- CNC Controller with USB & SD Card Support

- Safety Features

- Emergency Stop, Overload Protection

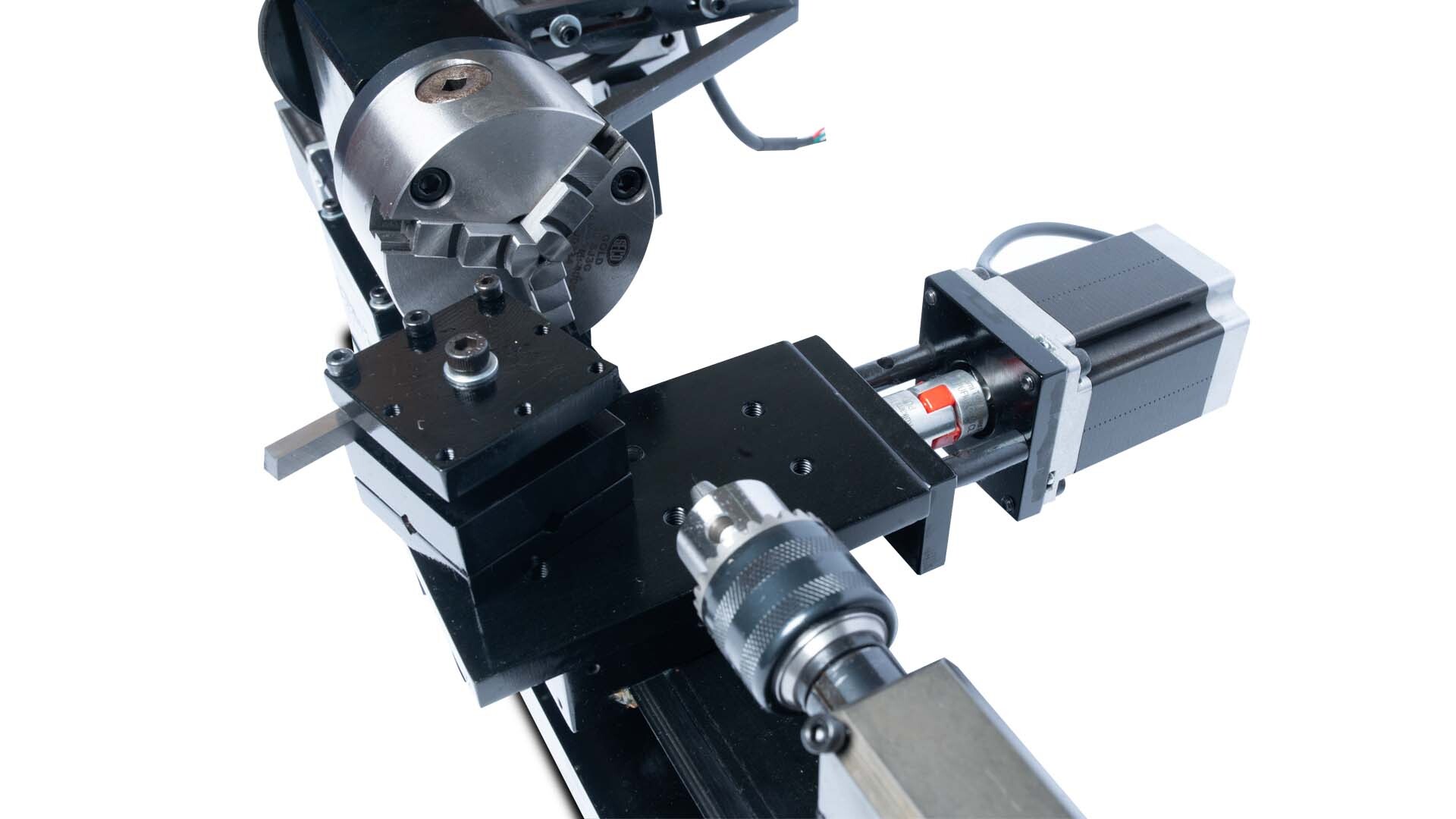

- Chuck Size

- 80 mm

- Lubrication System

- Automatic Centralized

- Coolant System

- Integrated

- Rapid Traverse Rate

- 8000 mm/min

- Tool Post

- 4-Station Turret

- Software Compatibility

- Compatible with G-Code, M-Code

- Repeatability Accuracy

- ±0.015 mm

- Maximum Workpiece Length

- 250 mm

- Tool Holder Type

- Quick Change

- Clamping Force

- 1.2 kN

- Display

- 7-inch LED LCD Touchscreen

Desktop CNC Lathe Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- Set

- Delivery Time

- 15 Days

About Desktop CNC Lathe

Having immense knowledge and know-how of our functional domain, we are engaged in manufacturing and supplying supreme quality Desktop CNC Lathe. The offered lathe is basically used for cutting, drilling and shaping of tools. Our provided lathe is manufactured from quality approved components and cutting-edge machinery under the guidance of our industrial experts. Available in different technical specifications, this Desktop CNC Lathe can be purchased from us at marginal prices.

Features:

-

Robust construction

-

Noise-free operations

-

Low power consumption

-

Minimum maintenance

Precision Engineering for Consistent Results

Featuring high structural rigidity and a repeatability accuracy of 0.015 mm, this desktop CNC lathe ensures exceptional precision during metal turning tasks. The cast iron bed and alloy steel components minimize vibration and maintain stability, making it ideal for intricate and prototype machining where exact measurements count. Whether for research labs or small-scale production, consistency is guaranteed.

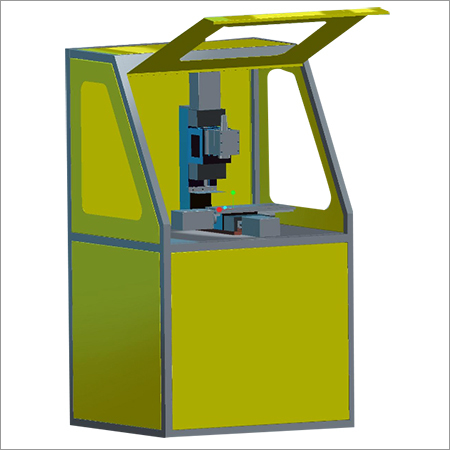

Enhanced Usability and Safety

Designed for both beginners and experienced operators, the CNC lathe offers a 7-inch touchscreen interface and supports USB and SD card connectivity for seamless program uploads. Safety is prioritized with emergency stop functionality and overload protection. The automatic centralized lubrication and integrated coolant system ensure smooth and safe operation during extended runs.

Versatile Application and Compact Design

Despite its compact footprint (760 x 600 x 580 mm), this CNC lathe accommodates a wide range of precision turning tasks, with a maximum turning diameter of 120 mm. The quick-change tool holder and 4-station turret accelerate setup times, while the machines low noise and efficient 1.5 kW servo motor make it suitable for workshops, training centers, and prototyping environments.

FAQs of Desktop CNC Lathe:

Q: How does the integrated coolant and lubrication system improve machine performance?

A: The integrated coolant system helps maintain optimal cutting temperatures, prolonging tool life and improving surface finish. The automatic centralized lubrication ensures that moving parts are consistently oiled, reducing wear and maintenance downtime.Q: What types of files can the CNC controller process, and how are they loaded?

A: The CNC controller is compatible with G-Code and M-Code files, common programming languages for CNC operations. Files can be loaded via USB flash drive or SD card using the 7-inch LED LCD touchscreen interface, enabling quick and user-friendly program management.Q: When should the emergency stop and overload protection features be used?

A: The emergency stop is designed for immediate shutdown in hazardous situations, protecting both the operator and the machine. Overload protection automatically intervenes when excessive loads are detected, preventing potential damage to internal components.Q: Where can this Desktop CNC Lathe be effectively utilized?

A: This lathe is suited for use in educational institutions, research labs, prototyping facilities, and small-scale precision manufacturing shops. Its compact size and versatility make it an excellent choice for environments with limited space.Q: What are the main benefits of the 4-station turret and quick-change tool holder?

A: The 4-station turret allows rapid switching between multiple tools during operations, increasing productivity. The quick-change tool holder streamlines tool replacement, saving setup time and ensuring consistent machining accuracy.Q: How do I maintain optimal repeatability and precision with this CNC lathe?

A: To maintain optimal precision (0.015 mm), ensure that the machine is regularly serviced, tools are sharp, proper lubrication is maintained, and cutting programs are validated before running. Routine checks of alignment and rigidity are also recommended.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Machines Category

CNC Mill Enclosure

Price 1.20000 INR

Minimum Order Quantity : 1 Set

Voltage : 220240V (customizable per machine)

Rigidity : Other, High structural rigidity for enhanced safety

Weight (kg) : Approximately 320 kg (depends on exact model and size)

Product Type : CNC Mill Enclosure

Tabletop CNC Lathe

Price 1.20000 INR

Minimum Order Quantity : 1 Set

Voltage : 220 V

Rigidity : Other, High rigidity cast iron bed

Weight (kg) : Approx. 110 kg

Product Type : Tabletop CNC Lathe

Tabletop Cnc Lathe Machine

Price 1.20000 INR

Minimum Order Quantity : 1 Set

Voltage : 220V

Rigidity : High

Weight (kg) : 80 kg

Product Type : Tabletop CNC Lathe Machine

Cnc Twin spindle Gearteeth chamfering machine

Price 1600000.0 INR / Set

Minimum Order Quantity : 1 Set

Voltage : 415 Volt (v)

Rigidity : High

Product Type : Twin spindle Gearteeth chamfering machine

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS