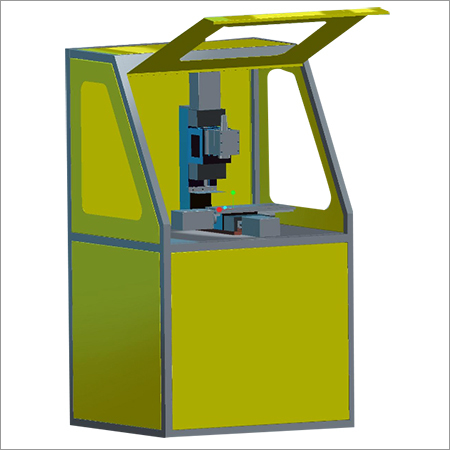

Tabletop CNC Mill

Tabletop CNC Mill Specification

- Product Type

- Tabletop CNC Mill

- General Use

- Metal Cutting, Prototyping, Education

- Material

- Aluminum & Steel

- Type

- Desktop CNC Milling Machine

- Capacity

- 5 kg workpiece

- Weight (kg)

- 65 kg

- Computerized

- Yes

- Automatic

- Semi-Automatic

- PLC Control

- Integrated

- Bar Feeder

- Not Included

- Power Source

- Electric

- Power Consumption

- 600 W

- Rigidity

- High

- Voltage

- 220 V

- Motor

- Stepping Motor

- Table Size

- 400 mm x 300 mm

- Spindle Speed

- 3000 rpm

- Axial Choice

- 3 Axis

- Dimension (L*W*H)

- 600 mm x 550 mm x 700 mm

- Feature

- Compact Design, High Precision, Low Noise

- Color

- White & Blue

- Controller Type

- CNC Controller with USB

- Cooling System

- Air Cooling

- Display

- Digital Touchscreen

- Travel Range (X/Y/Z)

- 350 mm / 250 mm / 120 mm

- Safety Features

- Emergency Stop, Limit Switches

- Tool Holder Type

- ER11

- Repeatability

- ±0.02 mm

- Lubrication

- Automatic Lubrication

- Software Compatibility

- Mach3, GRBL

- Interface

- USB, Parallel Port

- Max Tool Diameter

- 10 mm

- Spindle Power

- 0.8 kW

Tabletop CNC Mill Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- Set

- Delivery Time

- 15 Days

About Tabletop CNC Mill

Tabletop CNC Mill

Features:

- Compact and Light weight only 25 Kgs

- PC based system

- Perfect for small jobs machining.

- Easy to operate. Even a school student can learn to operate the machine within an hour.

- Very easy Electronic spindle speed adjustment.

- Spindle speeds infinitely variable from 100-3000 RPM.

- Prooven and user friendly Mach3 interface.

- Suitable for Engineering Colleges,ITIs and all types of small and medium Engineering and Hobby Shops.

Standards :

- Machine tool with three stepper motors on X,Yand Z axes

- DC motor with speed control unit for spindle

Options :

- Servo motors for all three axes and

- AC motor with VFD

|

Machine Specification |

Tabletop CNC Mill Model- TCM-01 |

|

X Axistraverse |

240mm |

|

Y Axistraverse |

150mm |

|

Z Axistraverse |

200mm |

|

Table Length with T Slot |

220mm X 75mm |

|

Spindle Inside Taper |

8 Deg (for ER16 collet) |

|

Spindle Speed |

100-300RPM Infinitely variable |

|

Cross Slide Indination |

0 Degrees |

|

Cutting Tool Size |

6*6mm |

|

Spindle motor DC Motor |

1 HP DC Motor, 2HP DC Motor, 1 HP |

|

Automatic Lubricat*xr- Points Provided |

Optional |

|

Input System |

Metric/ Inch |

|

Control Axes |

Simultaneous axes |

|

Interpolation |

Linear, Circular, elliptical and Parabolic, Slot milling, Rectangular and circular slot milling |

|

Minimum increment |

0.005mm |

|

Minimum Movement command-X |

0.005mm |

|

Minimum movement command-Z |

0.005mm |

|

Repeatability |

0.02mm |

|

Rapid Feed Rate X and Y |

400mm / min |

|

Raprd Feed Rate-Z |

800mm / min |

|

Dwell (Seconds) |

Programmable |

|

Backlash compensation |

Provided |

|

Speed override |

40%-160% |

|

Feed override |

20%-120% |

|

Type of Control system |

PC based system |

|

Real Time Tool Path simulation |

Provided |

|

General parameters |

|

|

Floor Area |

600mm x600 X 600 mm |

Compact Yet Powerful Design

Despite its desktop size, this CNC mill delivers industrial-level rigidity and precision. The sturdy aluminum and steel construction supports high-precision metal cutting and prototyping, while its modest footprint fits easily into most workshops, labs, or educational settings. Weighing just 65 kg, it can be installed with minimal space requirements and delivers quiet operation without compromising on performance.

Advanced Automation and Cooling Features

An integrated air cooling system and automatic lubrication prolong machine life and reduce maintenance needs. These features, coupled with a digital touchscreen and versatile CNC controller, enhance both usability and operational efficiency, making the machine suitable for semi-automatic production and rigorous educational use.

Safety and Connectivity

This CNC milling machine places operator safety at the forefront, with emergency stop buttons and position limit switches as standard. Flexible connectivity options include USB and parallel port interfaces, ensuring easy integration with various computers and established CNC software like Mach3 and GRBL for maximum control.

FAQs of Tabletop CNC Mill:

Q: How does the automatic lubrication system in the Tabletop CNC Mill operate?

A: The automatic lubrication system periodically dispenses lubricants to critical moving components, ensuring smooth motion, reducing friction, and minimizing wear. This process operates independently, requiring minimal intervention and resulting in reduced maintenance tasks for the user.Q: What materials is this CNC milling machine suitable for cutting or prototyping?

A: This CNC mill is constructed with a rigid aluminum and steel frame, making it well-suited for cutting and prototyping metals and other rigid materials. The high repeatability and precision ensure excellent results for both heavy-duty and detailed machining applications.Q: When should the air cooling system be used during machining?

A: The air cooling system is engineered to run during all machining processes, helping to dissipate heat generated by the spindle and tool. This prevents overheating, maintains consistent performance, and extends the lifespan of the spindle and cutting tools.Q: Where can this CNC mill be installed and utilized effectively?

A: Thanks to its compact dimensions and low operating noise, this CNC milling machine is ideal for small workshops, educational labs, prototyping centers, and research environments. Its semi-automatic function and digital controls make it accessible for both expert machinists and learners.Q: What is the primary benefit of the digital touchscreen and CNC controller integration?

A: The digital touchscreen simplifies operation by providing intuitive menu navigation, real-time status updates, and easy access to machine settings. Integration with a robust CNC controller allows seamless file transfers, precise motion control, and compatibility with popular software platforms like Mach3 and GRBL.Q: How does the emergency stop feature contribute to user safety?

A: The emergency stop button allows operators to immediately halt all machine operations in the event of an emergency. Coupled with limit switches, this feature minimizes the risk of accidental damage and ensures operator safety throughout the machining process.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Machines Category

Desktop CNC Lathe

Price 1.20000 INR

Minimum Order Quantity : 1 Set

Power Source : Electric

Voltage : 220V / 50Hz

Material : Other, Cast Iron Bed, Alloy Steel Components

PLC Control : Other, Available

CNC Mill Enclosure

Price 1.20000 INR

Minimum Order Quantity : 1 Set

Power Source : Electric

Voltage : 220240V (customizable per machine)

Material : Other, Powdercoated, heavygauge steel with polycarbonate viewing panels

PLC Control : Other, Optional integration available

Cnc Twin spindle Gearteeth chamfering machine

Price 1600000.0 INR / Set

Minimum Order Quantity : 1 Set

Power Source : Electric

Voltage : 415 Volt (v)

Material : Stainless Steel

PLC Control : Yes

Cnc Sliding Head Automatic Machine

Price 980000.0 INR / Set

Minimum Order Quantity : 1 Set

Power Source : Electric

Voltage : 415 Volt (v)

Material : Metal

PLC Control : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free