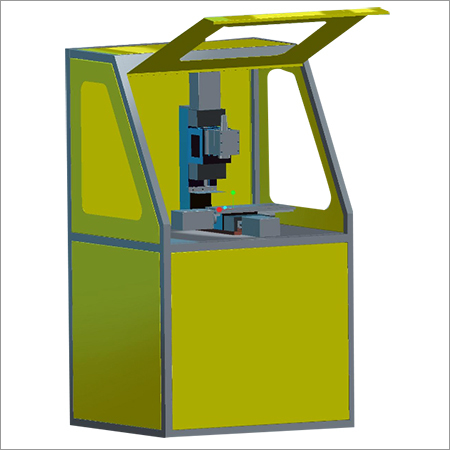

Tabletop Cnc Lathe Machine

Tabletop Cnc Lathe Machine Specification

- Product Type

- Tabletop CNC Lathe Machine

- Material

- Cast Iron, Steel

- Type

- Horizontal Lathe

- Capacity

- Max Turning Diameter 120 mm

- Weight (kg)

- 80 kg

- Computerized

- Yes

- Automatic

- Fully Automatic

- PLC Control

- Yes

- Bar Feeder

- Yes

- Power Source

- Electric

- Power Consumption

- 1.5 kW

- Rigidity

- High

- Voltage

- 220V

- Motor

- Stepper Motor

- Table Size

- 320 mm x 90 mm

- Spindle Speed

- 50 2500 rpm

- Axial Choice

- 2 Axis (X/Z)

- Dimension (L*W*H)

- 600 mm x 400 mm x 450 mm

- Feature

- Compact Design, Precision Engineering, Easy Operation

- Color

- Grey

Tabletop Cnc Lathe Machine Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- Set

- Delivery Time

- 15 Days

About Tabletop Cnc Lathe Machine

We are a renowned manufacturer and supplier of Tabletop CNC Lathe Machine to our widely spread clientele. IT is a PC based system that is easy to operate and has infinitely variable spindle speed ranging from 100 to 3000 RPM. It is widely used in small and medium engineering and hobby shops and colleges. Tabletop CNC Lathe Machine is available in various standards ad specifications and at highly cost- effective prices in the market.

Standards :

1.Machine tool with two stepper motors on X

and Z axes

2. DC motor with speed control unit for spindle

3. Precision Three jaw scroll chuck mounted on

spindle.

4. Tailstock with 6 mm drill chuck.

5. Four position manual tool turret.

Options :

1.Servo motors for all three axes and

2. AC motor with VFD

3. Tailstock with 10 mm drill chuck.

4.Four jaw dog chuck

5. Four position automatic tool turret

Mechanical specifications:

| System Specs: | |

| Part length | 1000 mm |

| Swing diameter | 200 mm |

| Follower stroke | 150 mm |

| Part Weight | 100 Kg |

| Spindle rpm (programmable) | 5 - 20 rpm |

| Radial Resolution | 0.05 um |

| Angular resolution | 0.0005 deg (1.8 arc-sec) |

| Machine dimensions: | |

| Height | 2000 mm |

| Width | 700 mm |

| Depth | 425 mm |

| Weight | 470 Kg |

Precision Performance in a Compact Design

This tabletop lathe combines advanced engineering and robust materials to achieve outstanding accuracy in every operation. Its small footprint makes it perfect for workshops with limited space, while its high rigidity and automated bar feeder allow for consistent and repeatable results, even during extended use.

User-Friendly Operation with Advanced Controls

Equipped with a computerized, PLC-controlled interface, the machine simplifies turning processes. Operators benefit from intuitive controls, easy programming, and automated functions, ensuring both beginners and experienced users can achieve high-quality output with minimal effort.

Versatile and Energy Efficient

Thanks to its electric power source and stepper motor, the lathe achieves reliable performance while consuming just 1.5 kW. The horizontal orientation and 2-axis movement enable adaptability for various material types, including cast iron and steel, making it an efficient choice for diverse turning projects.

FAQs of Tabletop Cnc Lathe Machine:

Q: How does the bar feeder improve the turning process on this tabletop CNC lathe?

A: The integrated bar feeder allows for automatic feeding of raw material, significantly increasing operational efficiency and reducing manual handling. This automation streamlines repetitive production tasks, resulting in consistent part quality and faster job completion.Q: What types of materials can this CNC lathe machine handle?

A: The machine is designed to work with both cast iron and steel, offering reliable machining for a wide range of parts and applications, whether prototyping or producing small batches.Q: When should I consider using a compact CNC lathe like this in my workshop?

A: This compact CNC lathe is ideal when you need precision turning capabilities but have limited space. It suits fabrication shops, educational settings, or small-scale manufacturing environments looking for automated and accurate machining.Q: Where can I install this CNC lathe and what are the space requirements?

A: With dimensions of 600 mm x 400 mm x 450 mm and weighing 80 kg, it is suitable for benchtop or workstation installation, requiring minimal floor space while maintaining operational stability.Q: What are the main benefits of the PLC-controlled and computerized features?

A: PLC control and computerized systems allow for precise programming, easy adjustments, and extensive automation. This leads to increased productivity, consistent quality, and easier integration into modern, digitalized manufacturing processes.Q: How is the machine operated and what kind of training is required?

A: Operation is simplified through an intuitive interface and automatic controls. Basic training on the control system and operational safety is generally sufficient, making the machine accessible for both skilled machinists and entry-level operators.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Machines Category

CNC Mill Enclosure

Price 1.20000 INR

Minimum Order Quantity : 1 Set

Material : Other, Powdercoated, heavygauge steel with polycarbonate viewing panels

Type : Other, Fully enclosed safety cabinet

Computerized : Other, No (enclosure only, not CNC controller)

Voltage : 220240V (customizable per machine)

Tabletop CNC Mill

Price 1.20000 INR

Minimum Order Quantity : 1 Set

Material : Other, Aluminum & Steel

Type : Other, Desktop CNC Milling Machine

Computerized : Yes

Voltage : 220 V

Cnc Twin spindle Gearteeth chamfering machine

Price 1600000.0 INR / Set

Minimum Order Quantity : 1 Set

Material : Stainless Steel

Type : Vertical

Computerized : Yes

Voltage : 415 Volt (v)

Cnc Sliding Head Automatic Machine

Price 980000.0 INR / Set

Minimum Order Quantity : 1 Set

Material : Metal

Type : Vertical

Computerized : Yes

Voltage : 415 Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free