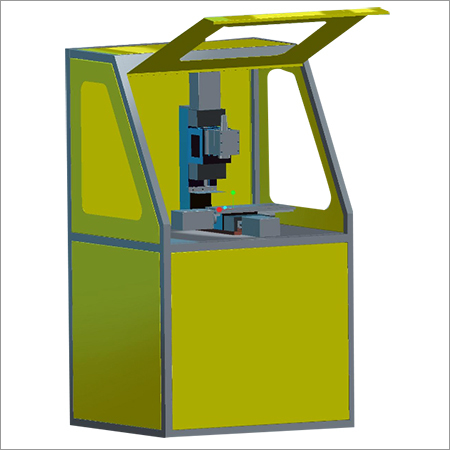

CNC Mill Enclosure

CNC Mill Enclosure Specification

- Product Type

- CNC Mill Enclosure

- General Use

- Machining workshop protection and safety

- Material

- Powder-coated, heavy-gauge steel with polycarbonate viewing panels

- Type

- Fully enclosed safety cabinet

- Capacity

- Compatible with light to heavy duty CNC mills

- Weight (kg)

- Approximately 320 kg (depends on exact model and size)

- Computerized

- No (enclosure only, not CNC controller)

- Automatic

- No (integrated with automatic CNC machinery)

- PLC Control

- Optional integration available

- Bar Feeder

- Not Included

- Power Source

- Electric

- Power Consumption

- Dependent on attached CNC mill specification

- Rigidity

- High structural rigidity for enhanced safety

- Voltage

- 220-240V (customizable per machine)

- Motor

- N/A (enclosure specific, not including spindle motors)

- Table Size

- Compatible with standard CNC mill beds (custom sizing available)

- Spindle Speed

- Dependent on installed mill

- Axial Choice

- Supports 3, 4, or 5 axis CNC machines

- Dimension (L*W*H)

- Approx. 2000 mm x 1500 mm x 1800 mm (varies by model)

- Feature

- Noise reduction, chip containment, coolant management

- Color

- Industrial grey (custom colors available)

- Sound Insulation

- Multi-layered structure for reduced operational noise

- View Panels

- Large, impact-resistant polycarbonate windows on multiple sides

- Door Type

- Twin sliding or front hinged doors with safety interlocks

- Fume Extractor Compatibility

- Ports provided for fume extraction system connection

- Sealing

- Sealed joints to prevent coolant and chip leakages

- Customization

- Available in custom sizes and material specifications on request

- Chip Tray

- Removable chip tray for easy maintenance

- Compliance

- CE and ISO safety standards

- Lighting

- Integrated LED task lighting

- Installation

- Includes base mounting and anchoring components

- Safety Switches

- Automatic power cut-off on door opening

- Coolant Drainage

- Integrated sloped base with drainage ports

CNC Mill Enclosure Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- Set

- Delivery Time

- 15 Days

About CNC Mill Enclosure

From the wide range of machines manufactured and supplied by us, we are indulged in providing excellent range of CNC Mill Enclosure. This enclosure is used for shaping three-dimensional parts of a solid materials. Manufactured by utilizing best-in-class components and advanced machinery, the provided enclosure is available in diverse technical specifications to withstand clients diverse requirement. In addition, this CNC Mill Enclosure is available with us at pocket friendly prices.

Features:

-

Easy to operate

-

Sturdy constructions

-

Low power consumption

-

Optimum performance

Comprehensive Safety Features

This enclosure ensures secure operation with automatic power cut-off when the doors are opened, sealed joints to prevent leaks, and multi-layered sound insulation to minimize operational noise. The large, impact-resistant viewing windows and internal LED lighting ensure clear visibility while safeguarding users.

Designed for Versatility and Compatibility

Supporting 3, 4, and 5 axis CNC mills, the enclosure accommodates both light and heavy-duty machines. It offers integrated coolant management and chip containment, and is compatible with fume extractors and various power requirements. Installation is streamlined using included base mounting and anchoring components.

Maintenance and Customization Options

For easy maintenance, the enclosure provides a removable chip tray and sloped drainage base. Customization is available for size, color, and material specification, ensuring the unit fits seamlessly into a variety of workshop layouts and operational requirements.

FAQs of CNC Mill Enclosure:

Q: How does the safety interlock system work on the enclosure doors?

A: The enclosures twin sliding or front hinged doors feature integrated safety interlocks, which automatically cut power to the CNC mill whenever a door is opened, ensuring operator safety during maintenance or tool changes.Q: What is the process for draining coolant and cleaning up chips inside the enclosure?

A: The enclosure includes a sloped base with dedicated drainage ports for efficient coolant management and a removable chip tray. This allows straightforward collection and disposal of metal chips and coolant residues, streamlining your maintenance routine.Q: When should I connect a fume extraction system to the enclosure?

A: It is recommended to connect the fume extractor whenever operations generate mist, smoke, or hazardous fumes. The enclosure is equipped with dedicated ports for easy attachment of standard fume extraction systems, enhancing workplace safety.Q: Where can this CNC mill enclosure be installed?

A: The enclosure is designed for use in machining workshops, tool rooms, educational facilities, or industrial plants. It includes base mounting and anchoring components for secure installation on standard shop floors.Q: What are the main benefits of the CNC mill enclosure?

A: Key benefits include enhanced operator safety, effective chip and coolant containment, substantial noise reduction, improved visibility, and compliance with CE and ISO safety standards. Its robust construction and flexible design ensure longevity and compatibility with diverse CNC installations.Q: How do I customize the size or color of the enclosure for my workshop?

A: Customization is available upon request; you can specify size, material, and color preferences to match your CNC machine and facility requirements when placing an order with the manufacturer or supplier.Q: Is the enclosure compatible with automatic mills and various spindle speeds?

A: Yes, it can be integrated with both automatic and manual CNC mills, accommodating a broad range of spindle speeds, bed sizes, and axis configurations. The enclosure itself does not include motors or controllers and is powered electrically via 220-240V (other voltages available on request).

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Machines Category

Tabletop CNC Mill

Price 1.20000 INR

Minimum Order Quantity : 1 Set

PLC Control : Other, Integrated

Material : Other, Aluminum & Steel

Type : Other, Desktop CNC Milling Machine

Automatic : Other, SemiAutomatic

Desktop CNC Lathe

Price 1.20000 INR

Minimum Order Quantity : 1 Set

PLC Control : Other, Available

Material : Other, Cast Iron Bed, Alloy Steel Components

Type : Other, CNC Lathe

Automatic : Other, SemiAutomatic

Tabletop Cnc Lathe Machine

Price 1.20000 INR

Minimum Order Quantity : 1 Set

PLC Control : Yes

Material : Other, Cast Iron, Steel

Type : Other, Horizontal Lathe

Automatic : Other, Fully Automatic

Cnc Twin spindle Gearteeth chamfering machine

Price 1600000.0 INR / Set

Minimum Order Quantity : 1 Set

PLC Control : Yes

Material : Stainless Steel

Type : Vertical

Automatic : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS