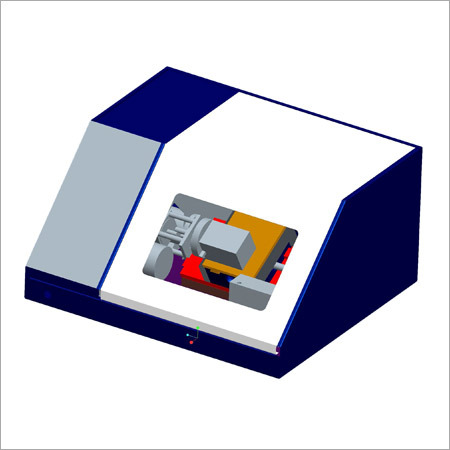

Table Top Cnc Lathe Machine

Price 225000.00 INR/ Unit

Table Top Cnc Lathe Machine Specification

- Product Type

- Table Top CNC Lathe Machine

- Material

- Cast Iron, Stainless Steel

- Cutting Thickness

- Up to 20 mm Millimeter (mm)

- Engraving Area

- Max. 200 mm x 300 mm Square Millimeter (mm2)

- CNC Or Not

- CNC

- Automatic Grade

- Automatic

- Control System

- Siemens/Fanuc Compatible

- Max. Swing Diameter

- 180 mm Millimeter (mm)

- Voltage

- 220V AC, Single Phase Volt (v)

- Weight (kg)

- ~180 kg Kilograms (kg)

- Dimension (L*W*H)

- 940 mm x 600 mm x 720 mm Millimeter (mm)

- Feature

- Other

- Color

- Grey / Custom

Table Top Cnc Lathe Machine Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 2 Sets, Set Per Day

- Delivery Time

- Days

About Table Top Cnc Lathe Machine

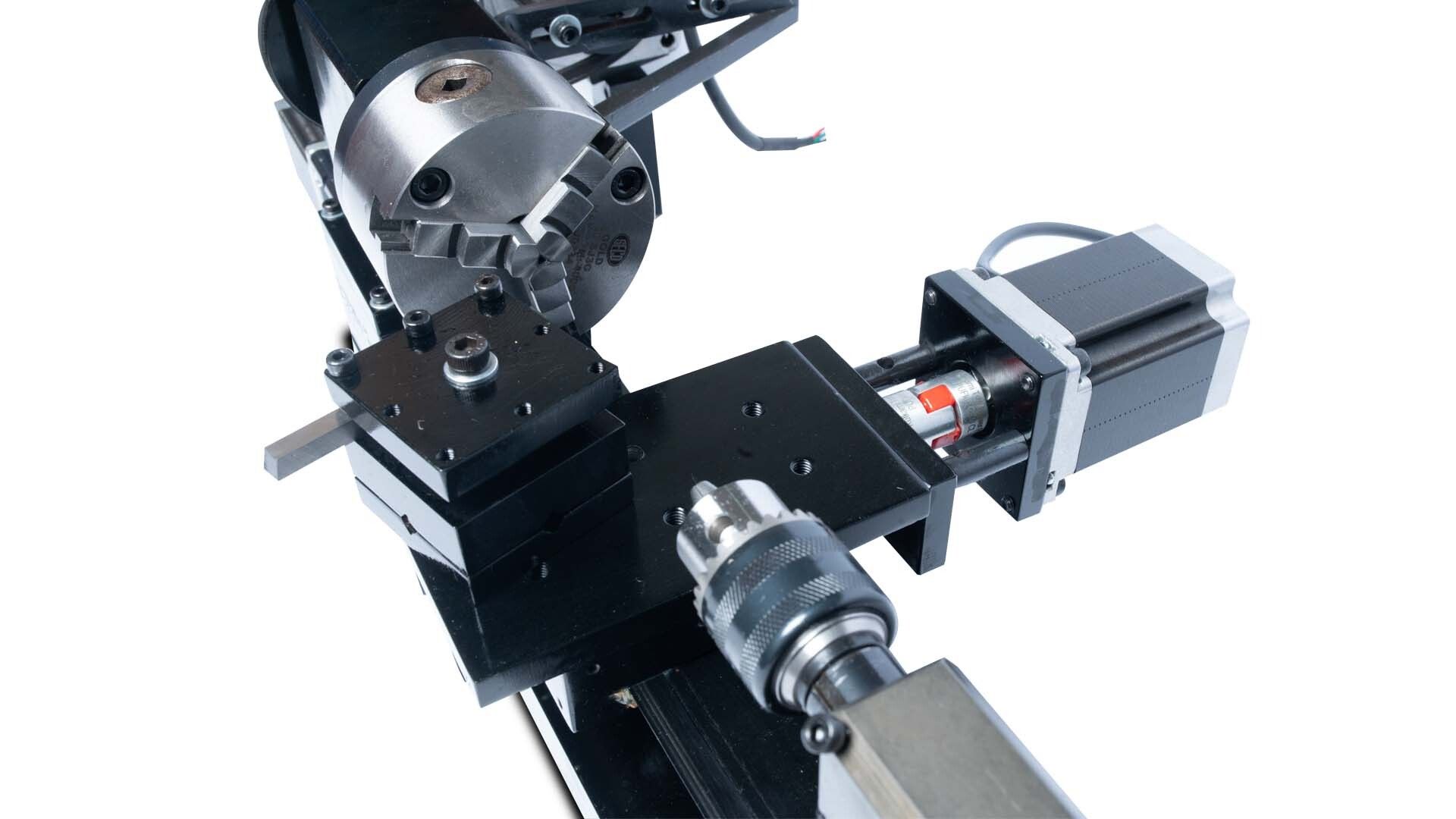

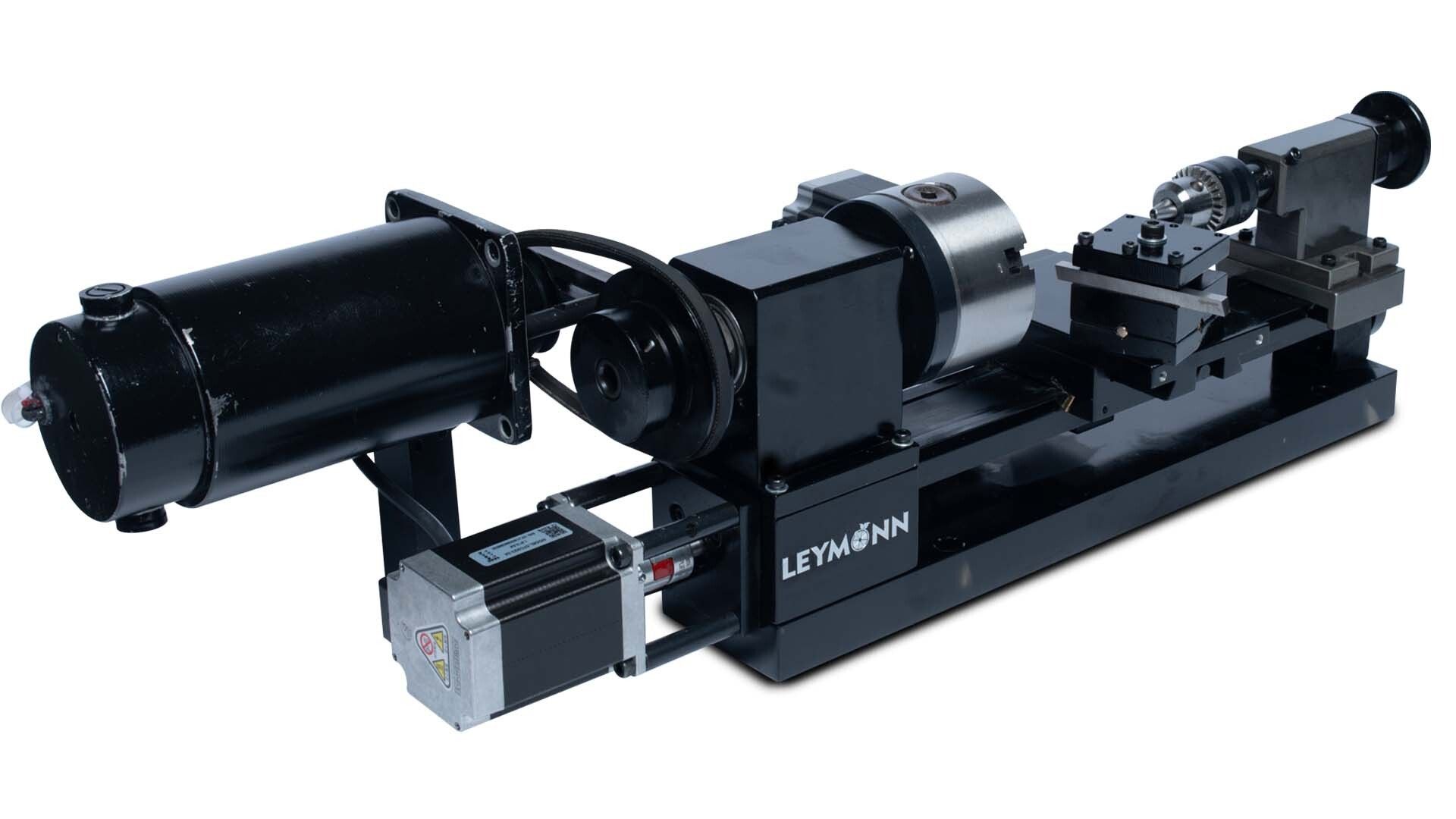

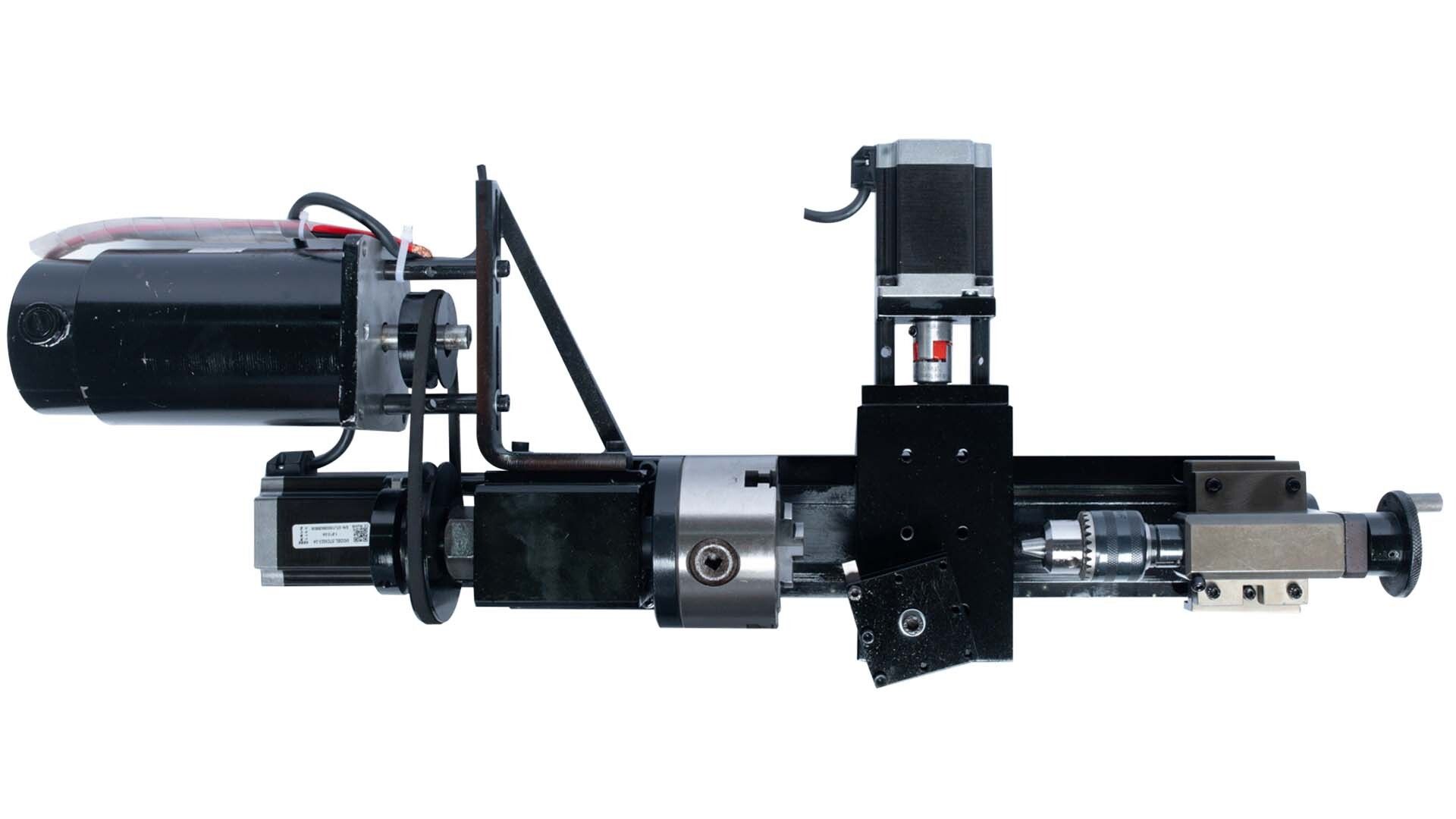

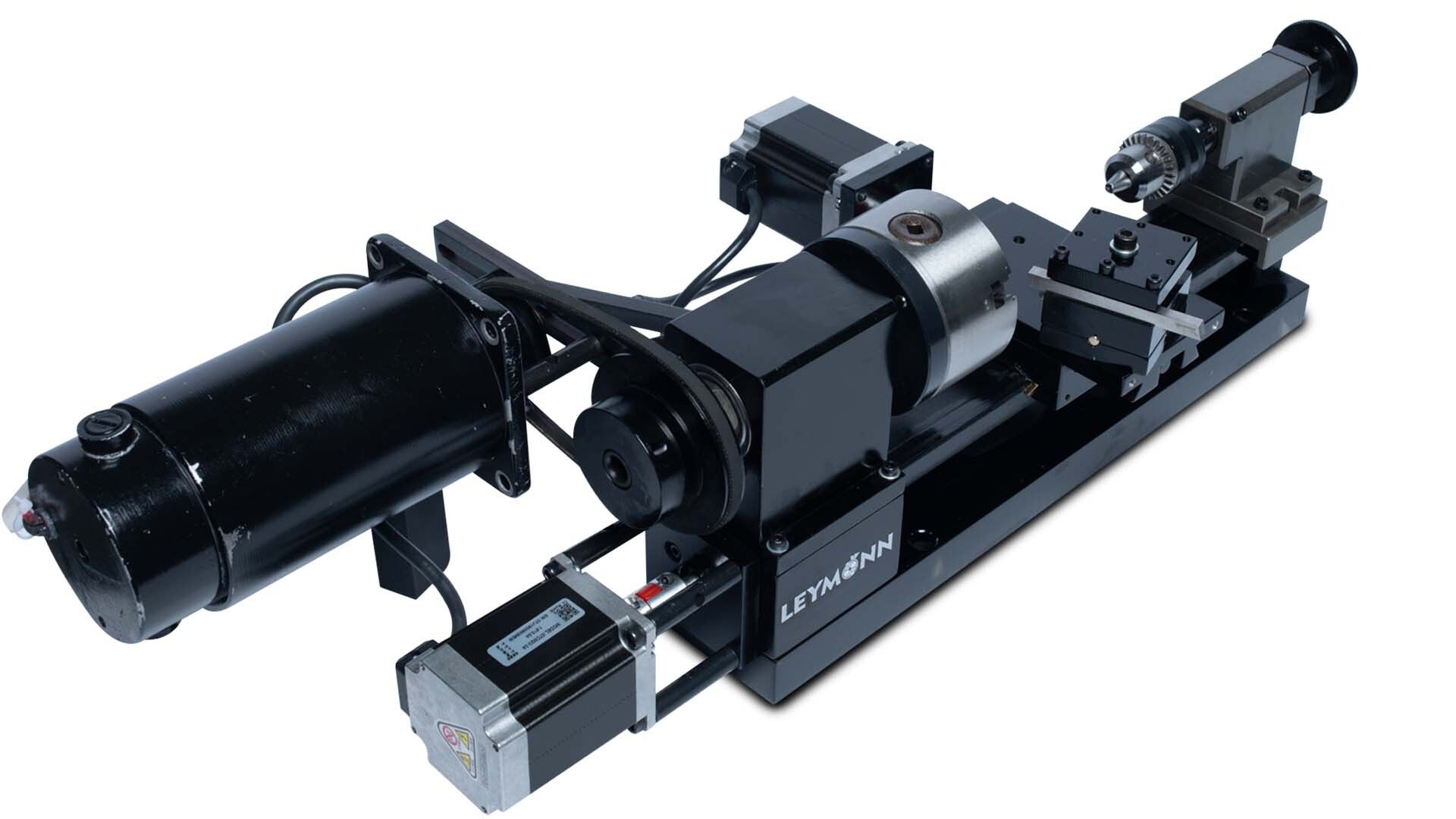

Our range of Table Top Cnc Lathe Machine are specially designed with international quality standards & premium quality raw material are sourced from certified vendors of the market & international quality standards.Compact and Reliable Construction

Designed with durable cast iron and stainless steel, the Table Top CNC Lathe Machine balances durability with a space-saving form factor. Its robust materials help dampen operational vibrations, ensuring high accuracy and longevity. The compact dimensions allow efficient placement in workshops where space is premium, making it suitable for small to medium-scale industrial applications.

Precision Cutting and Engraving Capabilities

This machine accommodates cutting thicknesses up to 20 mm and offers a generous engraving area of 200 mm x 300 mm. With a maximum swing diameter of 180 mm, it can handle a variety of intricate tasks. The automatic operation combined with CNC control ensures consistent and repeatable high-quality results suitable for both prototyping and production environments.

User-Friendly, Flexible Control System

Operators benefit from a user-friendly interface with compatibility for Siemens and Fanuc control systemsa standard in the industry. This flexibility allows easy integration into existing workflows and supports operators of different skill levels. The single-phase power option ensures convenient setup in most standard industrial settings.

FAQs of Table Top Cnc Lathe Machine:

Q: How does the Table Top CNC Lathe Machine benefit small workshops or businesses?

A: The compact footprint and high precision of this CNC lathe make it ideal for small workshops, enabling efficient use of limited space without sacrificing performance. The automatic and CNC-driven operation allows operators to achieve consistent, high-quality output with minimal manual intervention.Q: What materials can be processed using this CNC lathe machine?

A: Thanks to its robust cast iron and stainless steel construction and a cutting thickness capacity of up to 20 mm, the machine is capable of processing a broad range of materials including metals, plastics, and various composites, depending on tooling and application.Q: When should this machine be used over larger industrial lathes?

A: This table top CNC lathe is best utilized when precision tasks are required in confined or limited spaces, or when production batches do not justify the footprint or energy consumption of larger lathes. Its efficiency and high accuracy make it well-suited for prototyping, custom parts manufacturing, and continuous small-batch production.Q: Where can the Table Top CNC Lathe Machine be installed?

A: Due to its compact dimensions (940 mm x 600 mm x 720 mm) and single-phase 220V AC requirement, it can be installed in most industrial settings, educational institutions, small manufacturing units, or even upgraded home workshops with appropriate electrical supply.Q: What is the process for setting up and operating this machine?

A: Installation involves positioning the lathe on a stable surface, connecting to a 220V single-phase power supply, and configuring your chosen Siemens or Fanuc-compatible CNC control system. Once programmed, the automatic operation enhances productivity and ensures safety during continuous use.Q: How user-friendly is the interface for operators with varying skill levels?

A: The machine features an intuitive interface designed to accommodate both new and experienced users. Siemens and Fanuc compatibility ensures familiarity for most operators in the CNC field. Detailed manuals and support from the manufacturer or service provider further facilitate smooth onboarding and efficient operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lathe Machinery Category

Table Top Cnc Lathe

Price 260000 INR

Minimum Order Quantity : 1 Set

Product Type : Other, Table Top CNC Lathe

Control System : Other, Fanuc/Siemens Compatible

Material : Cast Iron, Hardened Steel

Dimension (L*W*H) : 850 x 610 x 620 mm

CNC Lathe Fabio

Price 35000 INR

Minimum Order Quantity : 1 Set

Product Type : Other, CNC Lathe

Control System : Other, FANUC/Siemens

Material : High grade cast iron and hardened steel

Dimension (L*W*H) : 2100mm x 1050mm x 1600mm

Tabletop Manual Lathe

Price 35000 INR / Set

Minimum Order Quantity : 1 Set

Product Type : Other, Tabletop Manual Lathe

Control System : Other, Handwheel Controls

Material : Cast Iron, Steel

Dimension (L*W*H) : 510 x 340 x 350 mm Millimeter (mm)

Desktop Lathe Machines

Price 35000 INR / Set

Minimum Order Quantity : 1 Set

Product Type : Other, Desktop Lathe Machine

Control System : Other, Manual

Material : Cast Iron

Dimension (L*W*H) : 820 x 350 x 280 mm Millimeter (mm)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS