Desktop Lathe Machines

Price 35000 INR/ Set

Desktop Lathe Machines Specification

- Product Type

- Desktop Lathe Machine

- Material

- Cast Iron

- Cutting Thickness

- Up to 20 mm Millimeter (mm)

- Control System

- Manual

- Max. Swing Diameter

- 180 mm Millimeter (mm)

- Voltage

- 220V AC Volt (v)

- Weight (kg)

- 70 Kilograms (kg)

- Dimension (L*W*H)

- 820 x 350 x 280 mm Millimeter (mm)

- Capacity

- High Precision Turning Kg

- Color

- Blue/Grey

Desktop Lathe Machines Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 10 Sets Per Month

- Delivery Time

- 15-20 Days

About Desktop Lathe Machines

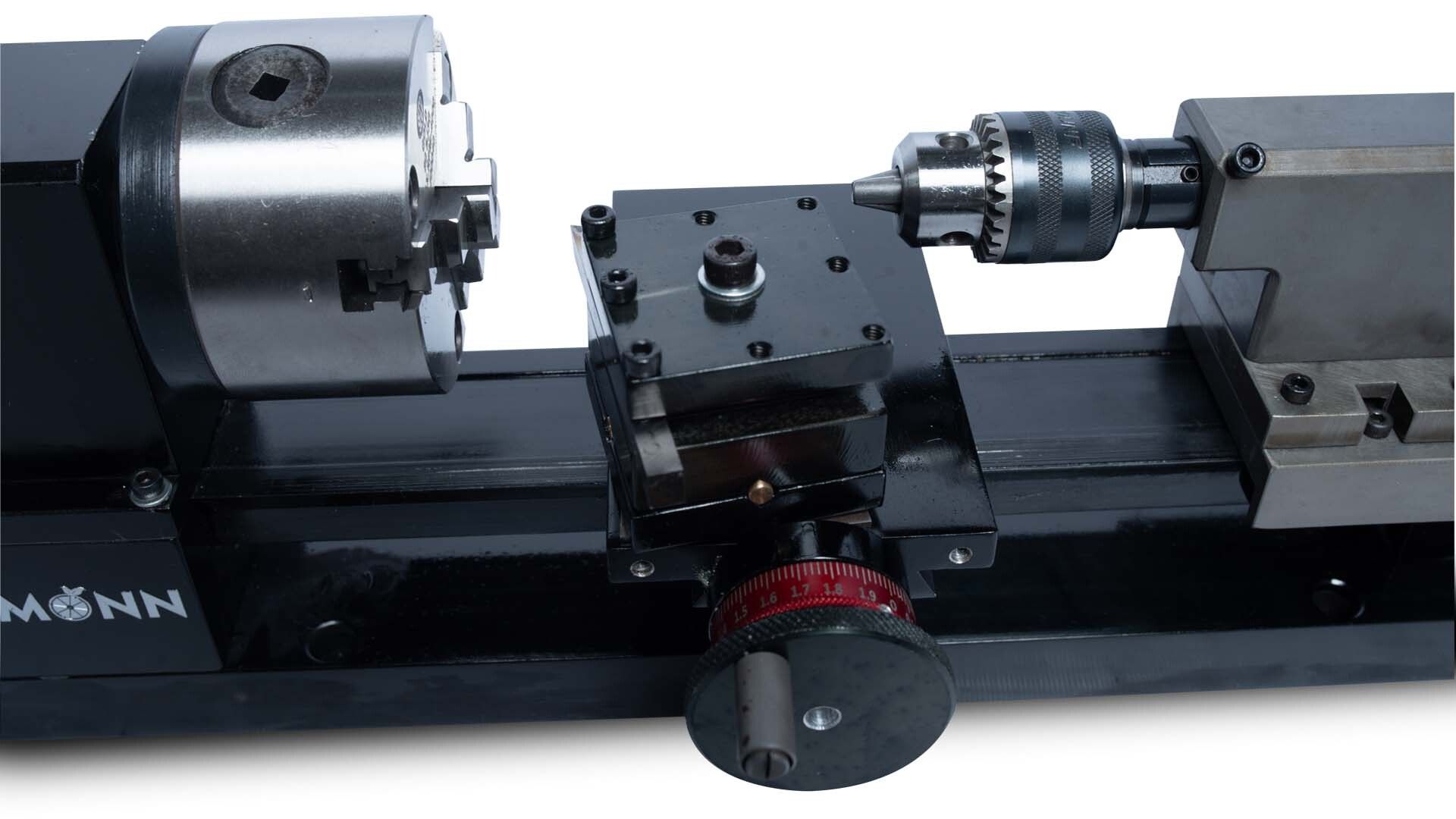

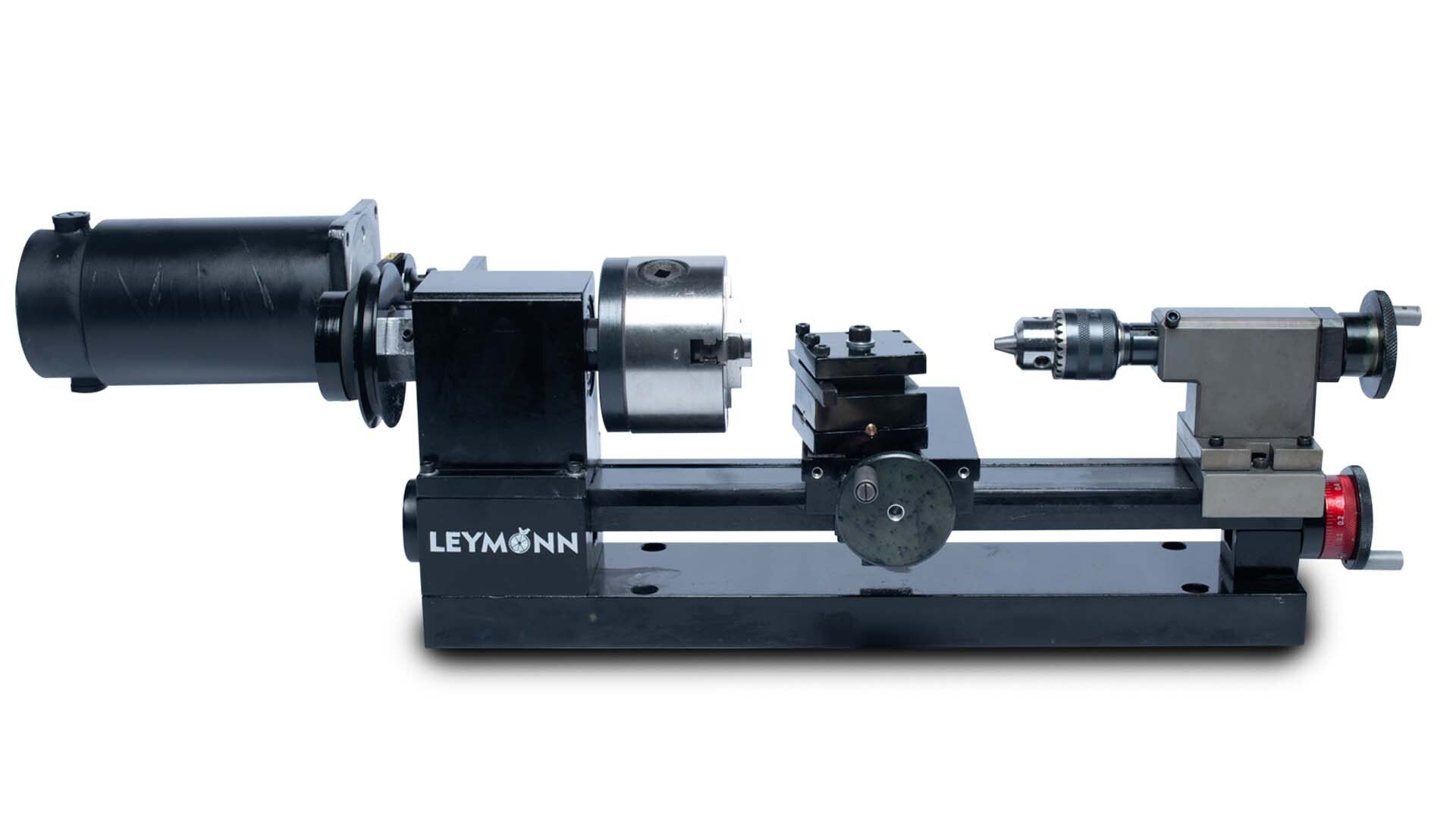

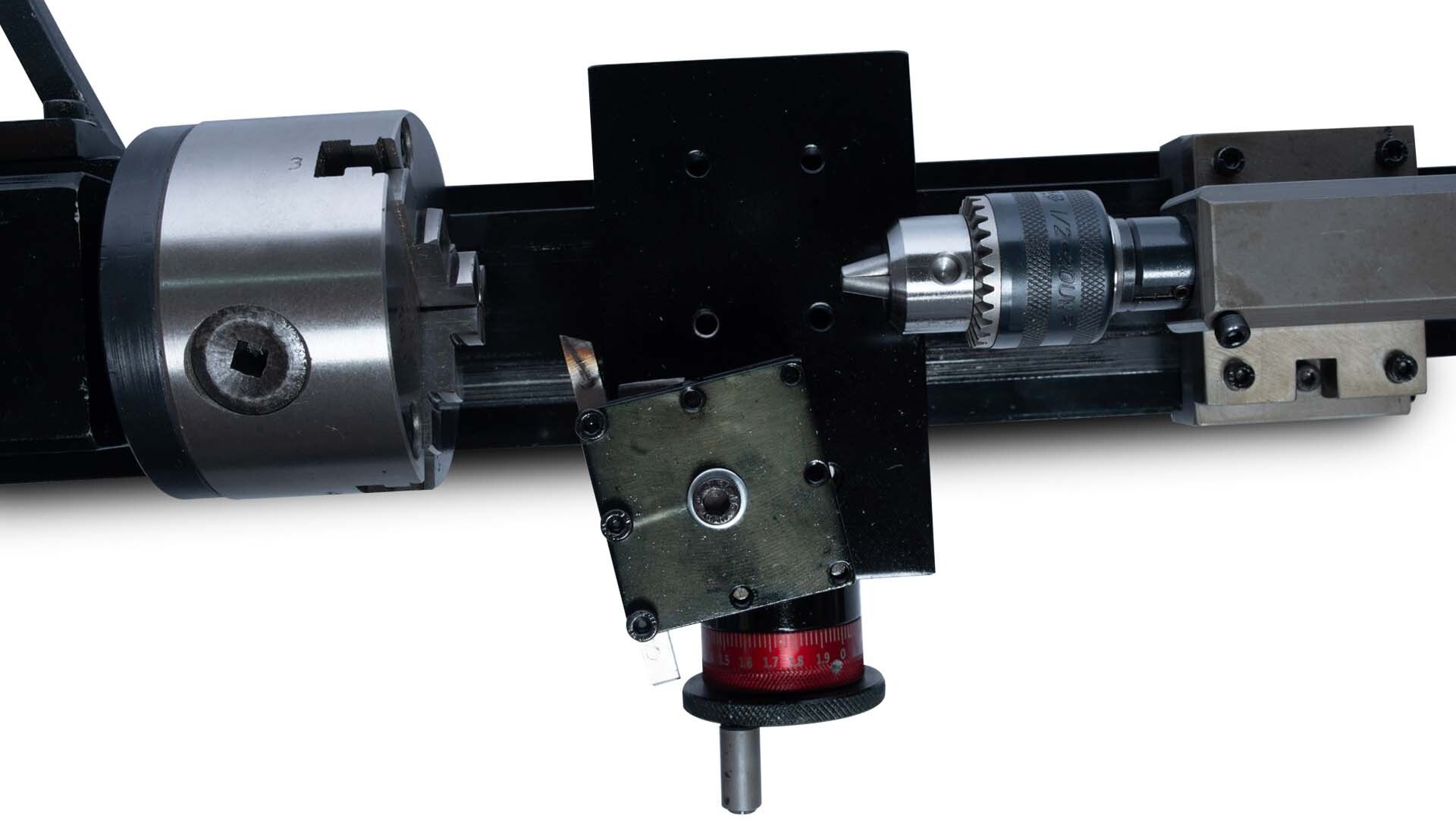

Octagon Desktop Lathe Machines (Tabletop Lathe)

The machine is capable of machining aluminum, brass, MS, EN8 and even stainless steel and of course nonmetals like nylon, delrin, wood etc.

The construction and appearance of the machine is very attractive and compact and can be stored in a cupboard after usage.

Technical Specifications

|

Swing over bed |

120mm |

|

Swing over carriage |

65mm |

|

Distance between centers |

160mm |

|

Hole through spindle |

10mm |

|

Cross slide travel |

60mm |

|

Longitudinal travel |

240mm |

|

Overall (lxwxh) |

680x190x190 |

|

Approx wt. |

15 kg |

Precision Engineering for Versatile Applications

Built to deliver accuracy and resilience, this desktop lathe excels in educational institutions, hobbyist workshops, and specialized tool rooms. Its 180 mm swing diameter, high-capacity turning, and easy-to-use manual controls make it the preferred choice for users who demand reliability and precise results. The single-phase electric power source ensures straightforward installation and operation.

Compact, Quiet, and Efficient

Designed with a footprint of just 820 x 350 x 280 mm and a weight of 70 kg, the lathe is both portable and space-saving. Despite its size, it maintains a noise level below 72 dB, making it ideal for environments where minimal disturbance is essential. Its variable speed gears and robust construction provide efficiency and adaptability for different turning tasks.

FAQs of Desktop Lathe Machines:

Q: How does the variable speed system benefit users of this desktop lathe machine?

A: The variable speed system offers precise control over the spindles rotation, enabling users to adjust the machining speed according to the material type and project requirements. This feature is especially useful for achieving high-quality finishes and optimizing the tools performance during diverse educational and hobby applications.Q: What materials can be worked on using this lathe, and what is its maximum cutting thickness?

A: This lathe machine, built from durable cast iron, can handle a variety of machinable metals and plastics. It supports a maximum cutting thickness of up to 20 mm, making it suitable for shaping, drilling, or threading small and intermediate-sized workpieces in instructional and workshop settings.Q: When is manual control preferred over CNC in educational or hobbyist environments?

A: Manual control is often favored in educational and hobbyist contexts because it allows users to develop fundamental machining skills and gain hands-on experience. This enhances the learning process and fosters a deeper understanding of lathe operations, unlike CNC, which often automates these essential tasks.Q: Where can this desktop lathe be effectively utilized?

A: Ideal for schools, vocational training centers, hobby workshops, and tool rooms, this lathe fits comfortably in compact spaces. Its lightweight and manageable dimensions make it a practical choice for environments with limited space but a requirement for high-precision turning capabilities.Q: What safety precautions should be followed when using this lathe machine?

A: Operators should always wear appropriate personal protective equipment such as safety glasses and gloves. Its essential to ensure the workpiece and tools are securely fastened before operation, avoid wearing loose clothing, and follow the manufacturers safety guidelines to prevent injuries.Q: How easy is it to install and maintain this lathe machine?

A: Installation is straightforward thanks to its single-phase 220V AC power source and compact design. Routine maintenance involves regular lubrication, thorough cleaning, and periodic inspection of components to ensure ongoing accuracy and a long service life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lathe Machinery Category

Table Top Cnc Lathe

Price 260000 INR

Minimum Order Quantity : 1 Set

Voltage : 220V, 50/60Hz

Control System : Other, Fanuc/Siemens Compatible

Color : White/Grey

Material : Cast Iron, Hardened Steel

CNC Lathe Fabio

Price 35000 INR

Minimum Order Quantity : 1 Set

Voltage : 380V/415V

Control System : Other, FANUC/Siemens

Color : Standard Industrial Grey

Material : High grade cast iron and hardened steel

Tabletop Manual Lathe

Price 35000 INR / Set

Minimum Order Quantity : 1 Set

Voltage : 220V / 50Hz Volt (v)

Control System : Other, Handwheel Controls

Color : Blue & Silver

Material : Cast Iron, Steel

Table Top Cnc Lathe Machine

Price 225000.00 INR / Unit

Minimum Order Quantity : 1 Set

Voltage : 220V AC, Single Phase Volt (v)

Control System : Other, Siemens/Fanuc Compatible

Color : Grey / Custom

Material : Cast Iron, Stainless Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free