PRECISION JET RECESS GRINDING MACHINE

MOQ : 1 Set

PRECISION JET RECESS GRINDING MACHINE Specification

- Product Type

- Jet Recess Grinding Machine

- General Use

- Recess and Groove Grinding

- Material

- Cast Iron Body

- Type

- CNC Grinding Machine

- Capacity

- Max Workpiece Diameter 150 mm

- Weight (kg)

- 3200 kg

- Computerized

- Yes

- Automatic

- Fully Automatic

- PLC Control

- Available

- Bar Feeder

- Not Included

- Power Source

- Electric

- Power Consumption

- 3.5 kW

- Rigidity

- High Rigidity Structure

- Voltage

- 380 V

- Motor

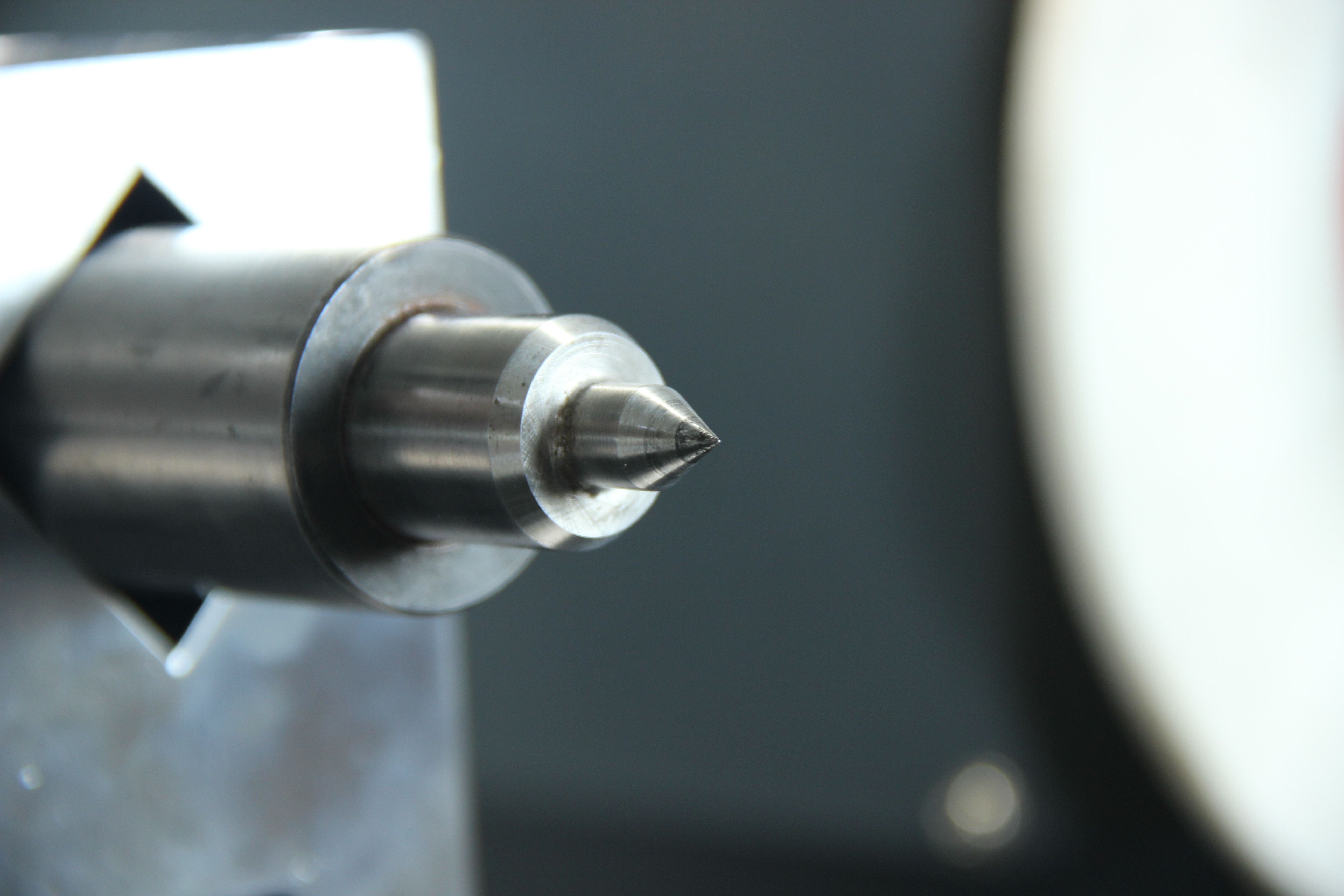

- Precision Spindle Motor

- Table Size

- 600 mm x 200 mm

- Spindle Speed

- Up to 3500 RPM

- Axial Choice

- X, Y, Z Axes

- Dimension (L*W*H)

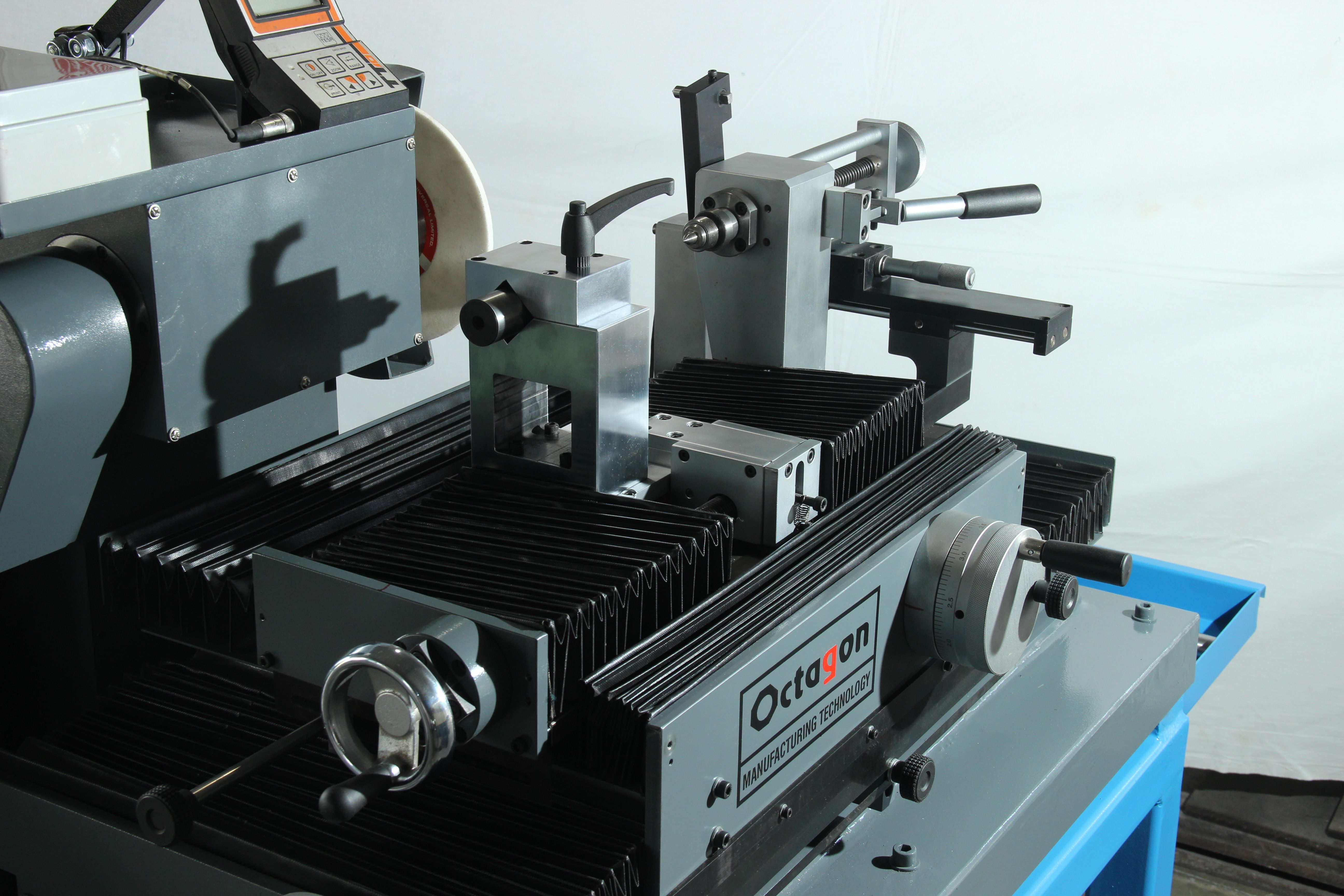

- 2200 x 1800 x 1800 mm

- Feature

- Precision Jet Grinding

- Color

- Industrial Grey

PRECISION JET RECESS GRINDING MACHINE Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- Set

- Delivery Time

- 15 Days

About PRECISION JET RECESS GRINDING MACHINE

PRECISION JET RECESS GRINDING MACHINE

SR. DESCRIPTION SPECIFICATION REMARKS

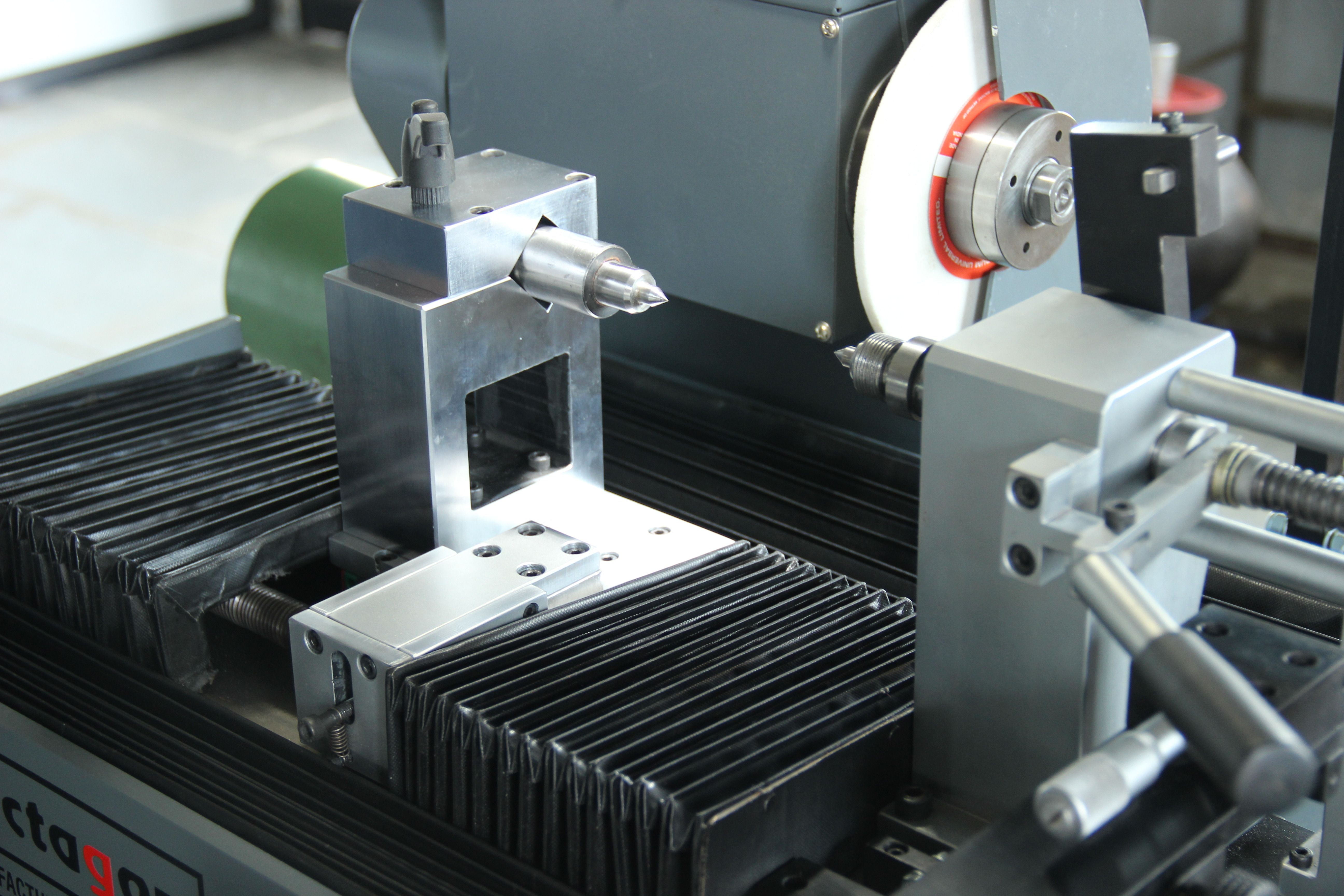

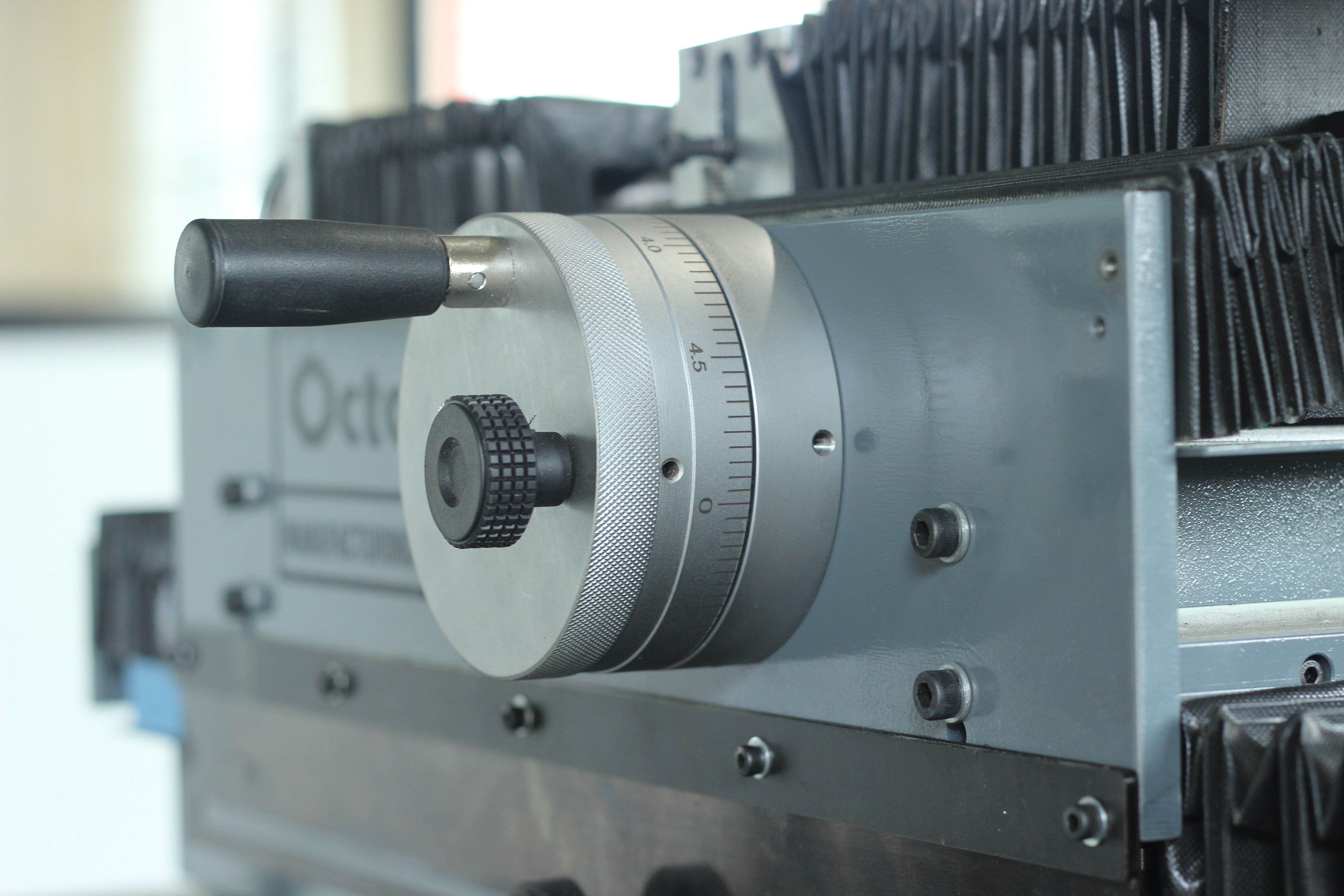

1 X AXIS TRAVEL 300 MM

2 Y AXIS TRAVEL 160 MM TO ACCOMMODATE DIA300MM PLUG

3 FINE ADJUSTMENT ON Y AXIS ± 5 mm LC 0.0005 mm

4 SPINDLE RPM 2800

5 GRINDING WHEEL DIA MAX 200 mm

6 TABLE HEIGHT FROM GROUND 900 mm

7 FOOTPRINT 1000X1000

8 INPUT POWER 230V/400V

Engineered for Superior Precision and Durability

Constructed with a highly rigid cast iron frame, this machine provides exceptional vibration control, leading to consistently precise grinding. The industrial grey finish signifies its durability, making it a reliable choice for heavy-duty environments in manufacturing and metalworking industries.

Advanced Automation and Control System

The CNC machine integrates PLC control and computerized operation, enabling seamless programming for intricate recess and groove grinding. This high-tech system enhances productivity by managing multiple axes (X, Y, Z) and ensuring repeatable results with minimal manual intervention.

FAQs of PRECISION JET RECESS GRINDING MACHINE:

Q: How is the Precision Jet Recess Grinding Machine operated?

A: This machine operates using advanced computerized controls with a PLC interface, allowing users to program complex grinding cycles. Its fully automatic nature minimizes manual handling while maintaining precise operation across the X, Y, and Z axes.Q: What materials can be processed with this grinding machine?

A: Thanks to its high rigidity and precision spindle motor, the machine efficiently handles various materials suitable for recess and groove grinding, including steel, alloys, and other industry-standard metals.Q: When should I consider using this grinding machine for my production line?

A: Use this CNC grinding machine when your workflow demands precise, repeatable, and automated recess or groove grinding on workpieces up to 150 mm in diameter and where high structural stability is crucial for consistent outcomes.Q: Where is the best installation setting for this machine?

A: It is best installed in industrial production environments with stable power supply (380 V) and adequate space for its dimensions (2200 x 1800 x 1800 mm), ensuring proper ventilation and accessibility for maintenance.Q: What is the typical process for grinding with this machine?

A: Operators load the workpiece, program the grinding cycle using the PLC control, and the machine automatically manages all grinding operations with high precision across all axes, delivering consistent groove or recess finishes.Q: How does the high rigidity structure benefit my operation?

A: The robust cast iron build minimizes vibration during grinding, resulting in high accuracy, stable output quality, and longer machine lifespan, making it ideal for demanding industrial use.Q: What are the usage benefits of the fully automatic feature?

A: The fully automatic, computerized operation reduces operator fatigue, increases throughput, and allows for consistent, high-precision grinding, ultimately improving productivity and reducing the risk of human error.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Our Infrastructure Category

Machinne Shop

Price 1.20000 INR

Minimum Order Quantity : 1 Set

Motor : Other, Powerful Induction Motor

Power Consumption : 3.7 kW

Power Source : Electric

Rigidity : Other, High structural rigidity

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS